Introducing the remarkable Nickel Alloy Seamless Tube by MT Stainless Steel, crafted specifically for the demanding conditions of the chemical industry. This product is in strict compliance with ASTM B163; ASTM B167; ASTM B444; ASTM B622 standards, ensuring the highest quality and safety.

Our Nickel Alloy Seamless Tube, constructed from a range of UNS grades including N10675, N10001, N10665, N10276, N06022, N08800, N08825, N04400, offers extraordinary resistance to hydrochloric acid at all intensities and temperatures. Besides, it effectively resists other nonoxidizing media like sulfuric, phosphoric, formic, acetic acids, offering excellent resistance to pitting corrosion, stress corrosion cracking, and knife line and weld heat-affected zone attack.

When it comes to application, our Nickel Alloy B-3 exhibits compatibility wherever Alloy B-2 is essential. Please note that it should not be used in the presence of ferric or cupric salts as this may instigate rapid corrosion attack.

What sets MT Stainless Steel apart is our stringent quality control. Quality is assured with a Mill Test Certificate issued with every shipment and a third-party inspection is always acceptable. Alongside, our product undergoes rigorous testing including Ultrasonic test, Eddy Current test, Mechanical Test (Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test), and Metal Test (Metallographic Analysis, Impact Test-High/low temperature).

Our commitment to customer satisfaction is our top-most priority. Be it FOB, CFR, or CIF, we offer flexible price items. Payments can be made via T/T or LC, and a delivery time of 30 working days post the receipt of your deposit is assured. Additionally, the packaging is tailored as per the customer's preference, be it an Iron case or woven bag. Choose reliability, choose MT Stainless Steel.

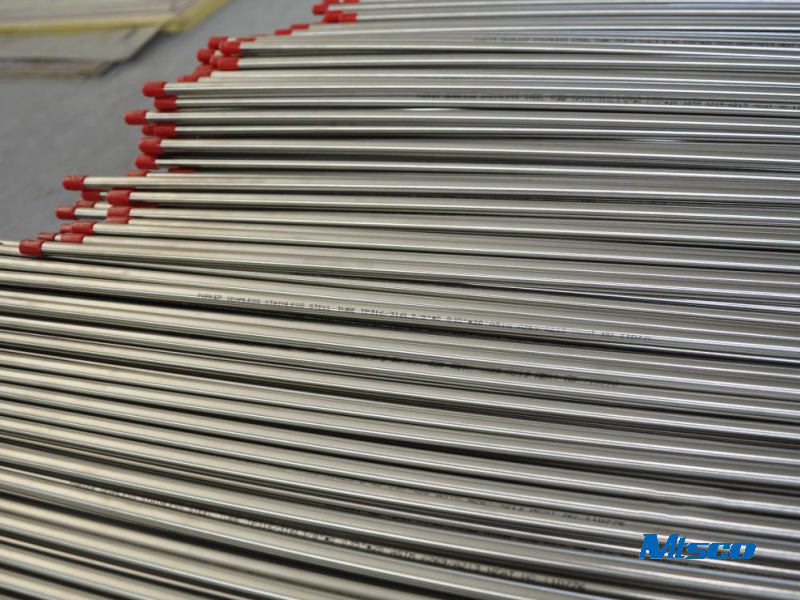

MT Stainless Steel introduces the finest quality Alloy C22 Tube, a seamless Nickel Alloy masterpiece specifically crafted for high-demand chemical industry applications. Renowned for its exceptional resistance to a wide range of chemicals, this seamless alloy tube stands out in the market.

Crafted from top-grade material featuring UNS N10675, UNS N10001, UNS N10665, UNS N10276, UNS N06022, N08800, N08825, N04400; our Alloy C22 Tube outperforms in durability, resistance to corrosion, and longevity. Its impressive outer diameter of 3 further enhances its usage potential and application versatility.

The Alloy C22 tube's seamless nature ensures superior finish and integrity, proving ideal for chemical industry requirements. Their seamless construction reduces the risk of weak points and leakages, making them a reliable choice for carrying hazardous and corrosive chemicals.

At MT Stainless Steel, we take pride in our commitment to quality and consistency that reflects in each Alloy C22 Tube we produce. Our meticulous attention to detail and stringent quality checks ensure the superior performance of our tubes. We understand the demanding nature of the chemical industry, and hence, we engineer our Alloy C22 tubes to meet and exceed these demands effortlessly.

Material Grade: UNS N10675, UNS N10001, UNS N10665, UNS N10276, UNS N06022, N08800, N08825, N04400; etc

Outer Diameter: 3.18mm-101.6mm

Wall Thickness: 0.5mm-20mm

Length: Normally fixed length 6m, can as per customer’s requirement

Standard: ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc

Technology : Cold Drawn / Cold Rolled

Features:

Nickel Alloy B-3 has outstanding resistance to hydrochloric acid at all concentrations and temperatures. It also resists sulfuric, phosphoric, formic, acetic acids and other nonoxidizing media. It has excellent resistance to pitting corrosion, stress corrosion cracking, and knife line and weld heat-affected zone attack. Hastelloy B-3 has greater thermal stability than Alloy B-2.

Applications:

Alloy B-3 is suitable for the applications where Alloy B-2 is required. Like Alloy B-2, Alloy B-3 should not be used in the presence of ferric or cupric salts as these salts may cause rapid corrosion attack.

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) |

| Package | Iron case; woven bag or as per customer’s requirement |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

| Quality | Test | NTD(Ultrasonic test, Eddy Current test); |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test); |

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature); |

| Chemical Analysis(Photoelectric Emission Spectroscopic) |

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Previous:Alloy B-2 / UNS N10665 ASTM B622 Nickel Alloy Annealed&Pickling Tube For Chemical Process IndustryNext:Alloy C276 Nickel Alloy Smls Tube With BA/AP Tube ASTM Standard For Oil Service

Experience the difference of our Alloy C22 Tube, a seamless combination of strength, durability, and unparalleled performance. Ideal for challenging chemical industry applications, our tubes stand as a testament to our unwavering commitment to deliver nothing but the best.

With MT Stainless Steel's Alloy C22 Tube, experience seamless integration, longevity, and a peace of mind that comes with knowing you have chosen the best.