Enhance Oil & Gas Extraction with MT Stainless Steel's Downhole Control Line Tubing

Grade | Alloy 825/N08825, Alloy 625 /N06625, Alloy 400/ N04400, 2205, 2507, TP316/L, TP304/L, etc |

Type | Welded |

Hole count | Single/Multi Core |

Outer Diameter | 1/4”, 3/8”, 1/2” |

Wall Thickness | 0.035”, 0.049’’, 0.065” |

Length | According to customers’ needs, up to 10000m |

Standard | ASTM A269/A213/A789/B704/B163,etc. |

Certificate | ISO/CCS/DNV/BV/ABS, etc. |

Inspection | NDT; Hydrostatic test |

Package | Wooden or iron reel |

Features of Nickel Alloy 625 Coiled Tubing

High creep fracture strength

Resistant to oxidation at 1800°F

Good fatigue resistance

Excellent weldability

Excellent resistance to chloride pitting and crevice corrosion

Resistant to chloride ion stress corrosion cracking

Resistant to seawater under flowing and stagnant conditions as well as under contaminated conditions

|  |

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

| Package | Wooden or iron reel or as per customer’s requirement | |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

| Quality | Test | NDT(Ultrasonic test, Eddy Current test) |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test) | ||

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature) | ||

| Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

An increasing number of projects in the oil service industry require the use of continuous lengths of nickel alloy control lines. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex control lines. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.

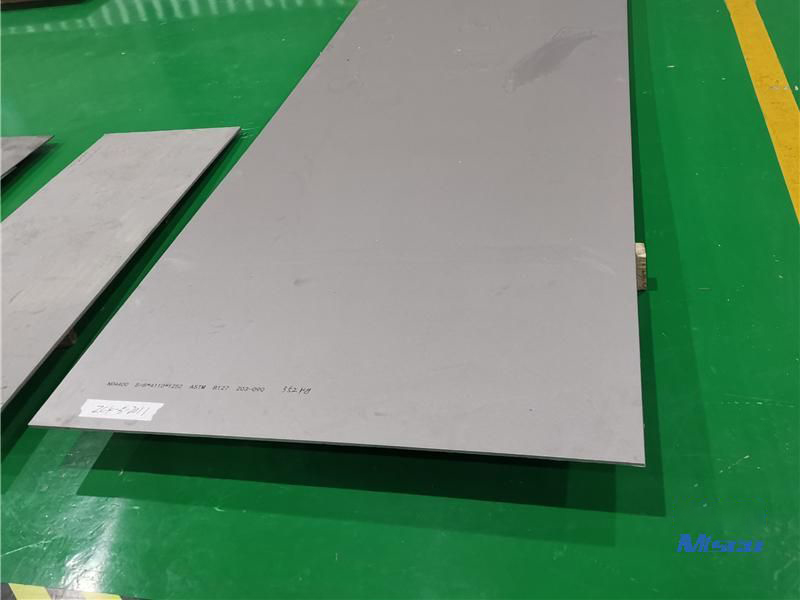

Previous:Nickel Alloy 400/UNS N04400 Chemical Encapsulation Control Line Tubing With BV CertificateNext:ISO/ PED Certified Nickel Alloy C276/ UNS N10276 Sheet with Cold Rolling forGeothermal

At MT Stainless Steel, we comprehend the unique challenges of the oil and gas industry. It's why we've incorporated a pioneering technology into our downhole control line tubing, aiming to augment your extraction methods while decreasing the risks involved. We believe in not just delivering a product, but a solution. A solution that efficiently caters to your needs, securing your investments, and leading you to the forefront of your industry. In the world of oil and gas extraction, our Downhole Control Line Tubing is more than just a tool; it's the lifeblood of your operations. Trust in our consistency, bank on our reliability, and thrive on our versatility. Welcome to a world of uncompromised quality and unmatched efficiency with MT Stainless Steel – the epitome of innovation in downhole control line solutions.