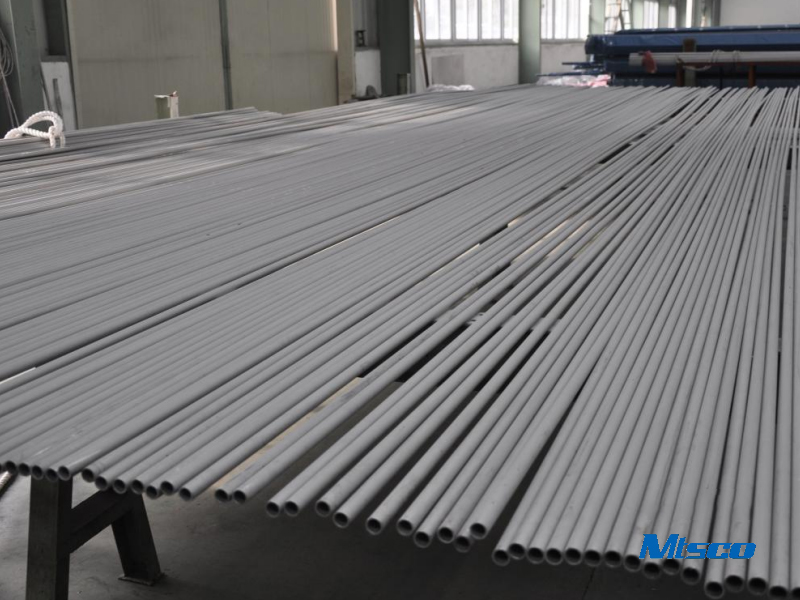

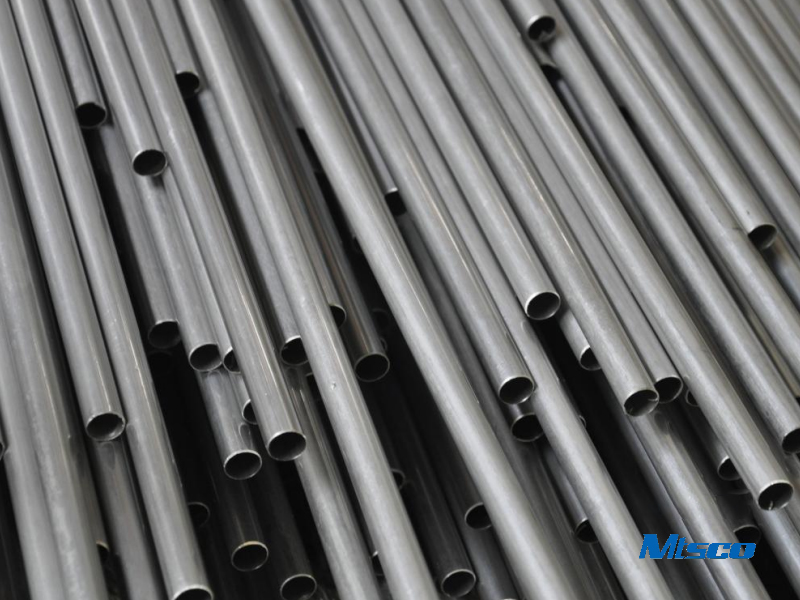

Exceptional Inconel Pipe - Custom-Made Nickel Alloy C22 Seamless Tube by MT Stainless Steel

Features:

Nickel Alloy C-22 is a versatile Ni-Cr-Mo-W alloy with better comprehensive corrosion resistance performance than other Ni-Cr-Mo alloys, including Alloy C-276, Alloy C-4 and Alloy 625. Alloy C-22 has outstanding resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chloride ions. It also offers optimum resistance to environments where reducing and oxidizing conditions are encountered in process streams. So it can be used where “upset” conditions are likely to occur or in multi-purpose plants.

Nickel Alloy C22 Chemical composition

| % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | P | S | V |

| min | balance | 20.0 | 12.5 | 2.0 | 2.5 | |||||||

| max | 22.5 | 14.5 | 6.0 | 3.5 | 2.5 | 0.015 | 0.50 | 0.08 | 0.020 | 0.020 | 0.35 |

1. Grade : UNS N06022, N06625 ,N06600 , N06601 , N07718 , N10276 , N08800 , N08825 ,N04400 ; etc

2 . OD ( Outer Diameter ) : 6.35mm to 114.3mm

3 . WT ( Wall Thickness ) : 1.65mm to 20mm

4 . Length : As customer’s requirement

5 . Standard : ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc

6 . Technology : Cold Drawn / Cold Rolled

| Application | a) Heat exchanger |

| b) Condenser | |

| c) Shipping industry | |

| d) Precision machinery | |

| e) Mechanical structure industry | |

| f) Thermocouple & Cable etc |

|  |

Previous:Alloy C276 Nickel Alloy Smls Tube With BA/AP Tube ASTM Standard For Oil ServiceNext:Nickel Alloy C-4 ASTM B564 Seamless Nickel Alloy Tube With Annealed&Pickling Used in Acidic Environment

Moreover, the presence of Molybdenum and Tungsten in the alloy composition further enhances the product's resistance to both oxidizing and reducing conditions, thus making it the perfect choice for applications in diverse environmental conditions. The superior corrosion resistance, coupled with the robust construction of our Inconel Pipe, ensures that it will stand the test of time and deliver reliable performance consistently. At MT Stainless Steel, we have a tradition of providing our clients with products of exceptional quality, and our Inconel Pipe is no exception. Designed to perfection, this product is the embodiment of our commitment to quality and customer satisfaction. Our Inconel Pipe, a custom-made Nickel Alloy C22 Seamless Tube, is not just a product; it is a testament to our commitment to innovation, quality, and performance. Discover the supreme properties of our Inconel Pipe today for your industrial needs.