Exceptional Monel Pipe: MT Stainless Steel's ASTM B704 Nickel Alloy 625 Control Line Tubing

ASTM B704 Nickel Alloy 625/UNS N06625 Control Line Tubing for Logging Cable

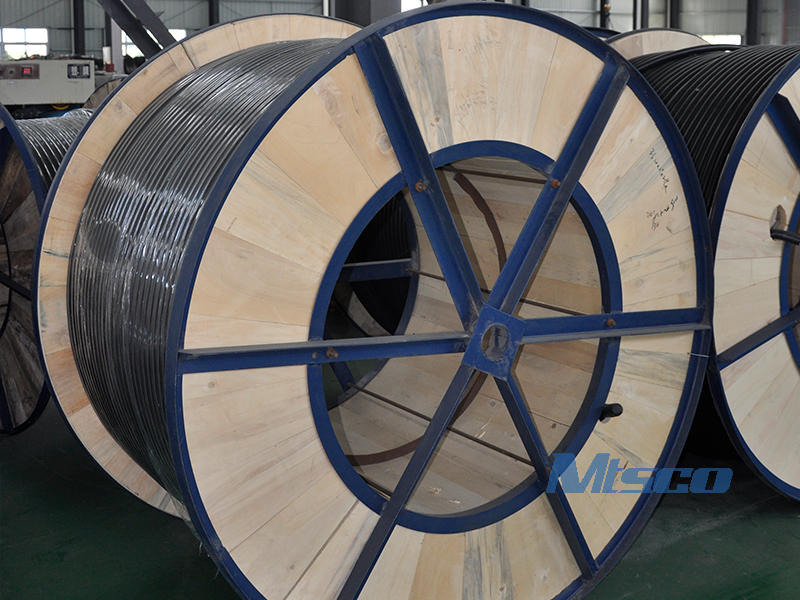

MTSCO cables are used to transmit signals, monitor and supply power in downhole applications where various downhole production data needs to be collected and channels established with the formation during oil and gas production. For the tubing, we mainly supply materials of stainless steel, duplex steel and nickel alloy (such as 304/L,316/L, 2205, 2507,alloy 625, alloy 825). Diameters from 4mm to 88.9mm and our length can be up to 33000ft (10000m).

And MTSCO can supply cables of fiber cable, composite cable, logging cable and heating cable. For oil and gas wells that have experienced production declines or shutdowns due to fluid accumulation, fouling, waxing, or corrosion, MTSCO cables can be targeted to help you solve the problem.

Nickel Alloy 625 Chemical composition:

% | Ni | Cr | Mo | Fe | C | Mn | Si | P | S | Co | Nb+Ta | Al | Ti |

min | 58.0 | 20.0 | 8.0 | 3.15 | |||||||||

max | 23.0 | 10.0 | 5.0 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 1.00 | 4.15 | 0.40 | 0.40 |

Features: Alloy 625 has excellent strength at temperatures up to 816℃. At higher temperatures, its strength is generally lower than that of other solid solution strengthened alloys. Alloy 625 has good oxidation resistance at temperatures up to 980℃ and shows good resistance to aqueous corrosion, but is relatively moderate compared to other more capable corrosion resistant alloys.

Applications: Chemical process industry and sea water application. Inconel 625 is used in short term applications at temperatures up to 816℃. For long term service, it is best restricted to a maximum of 593℃, because long term exposure above 593℃ will result in significant embrittlement.

Previous:Fiber Cable with Nickel Alloy Inner Tube Alloy 600/625 for Downhole ToolsNext:Nickel Alloy 825/ UNS N08825 Control Line for Composite Cable

But what sets our Monel Pipe apart is the use of Nickel Alloy 625 (also known as UNS N06625), a corrosion-resistant alloy that provides high strength, excellent fabricability, and outstanding weldability. This superior alloy not only fortifies the tubing's structure but also increases its functionality and lifespan. Trust in MT Stainless Steel's Monel Pipe, a product that combines superior quality, performance, and design. Invest in the reliability of ASTM B704 Nickel Alloy 625 Control Line Tubing. Experience the unrivaled strength, and durability that our Monel Pipe offers, ensuring productivity and efficiency in every operation. With MT Stainless Steel's Monel Pipe, excellence is not just a promise, but a guarantee.