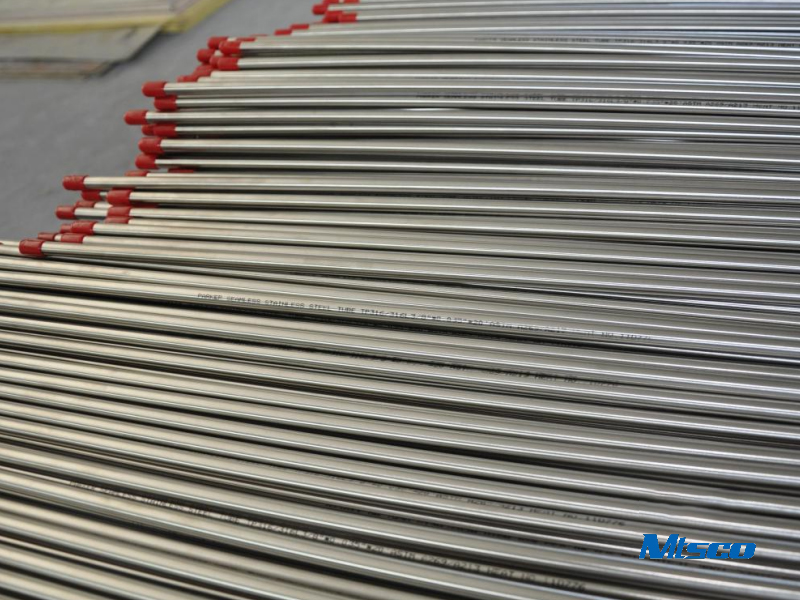

Exceptional Monel Pipe: MT Stainless Steel's Superior Alloy 600/Inconel 600/Nickel Alloy Seamless Tubes

| Grade | Alloy 600 / N06600 ,Alloy 625 / N06625 , Alloy 601 / N06601 , Alloy 718 / N07718, Alloy C276 / N10276 , Alloy 800 / N08000 , Alloy 825 / N08825 , Alloy 400 / N04400,etc |

| Standard | ASTM B622; ASTM B516; ASTM B444; ASTM B829, etc |

| Size | OD :6mm-355.6mm |

| WT : 0.75mm-20mm | |

| Length : According to customer needs up to 20m |

| Industry & Advantage | Application | Alloy 600 has good resistance to corrosion and high temperature and has high strength and good fabricability. It resists chloride-ion-incurred stress corrosion cracking, sulfur compounds and oxidizing conditions at high temperatures. |

| Advantages | Chemical process equipment, crude oil stills, gasoline and fresh water tanks, marine engineering equipment, valves, pumps and fasteners. | |

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

| Package | Iron case; woven bag or as per customer’s requirement | |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

| Quality | Test | NTD(Ultrasonic test, Eddy Current test) |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test) | ||

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature) | ||

| Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Alloy 600 Heat Exchange Tube Chemical composition:

% | Ni | Cr | Fe | C | Mn | Si | S | Cu |

min | 72.0 | 14.0 | 6.0 | |||||

max | 17.0 | 10.0 | 0.15 | 1.00 | 0.50 | 0.015 | 0.50 |

Through more than ten years of research and development, the production of MTSCO Alloy technology and efficiency of various materials have been greatly improved. The enterprise has passed the national quality management system certification of weapons and equipment, obtained more than 24 authorized patents, participated in the revision of 9 national standards and 3 industry standards. MTSCO has actively participated in the civil military integration project, provided high-temperature alloy materials for a PLA unit, provided high-quality special alloy materials for China ordnance industry group, and provided new low expansion alloy materials for China aviation industry. It has been successfully applied to the domestic large aircraft C919, replacing imports with domestic ones, breaking the foreign blockade monopoly and filling the domestic blank.

Previous:Alloy 601 / UNS N06601 Seamless Nickel Alloy Tube For Oilfield DownholeNext:Alloy 625/ UNS N06625 Nickel Alloy AP/BA Tube For Heat Exchanger Corrosion Resistance In High Temperature Environment

At MT Stainless Steel, we understand that every detail matters. That's why we incorporate innovative design and state-of-the-art manufacturing techniques into our pipeline solutions, delivering products that exceed expectations. Explore our superior range of monel pipes today and equip your operations with the best in the industry. With MT Stainless Steel, you're not just investing in a product - you're partnering with a name synonymous with excellence in the field of stainless steel solutions.