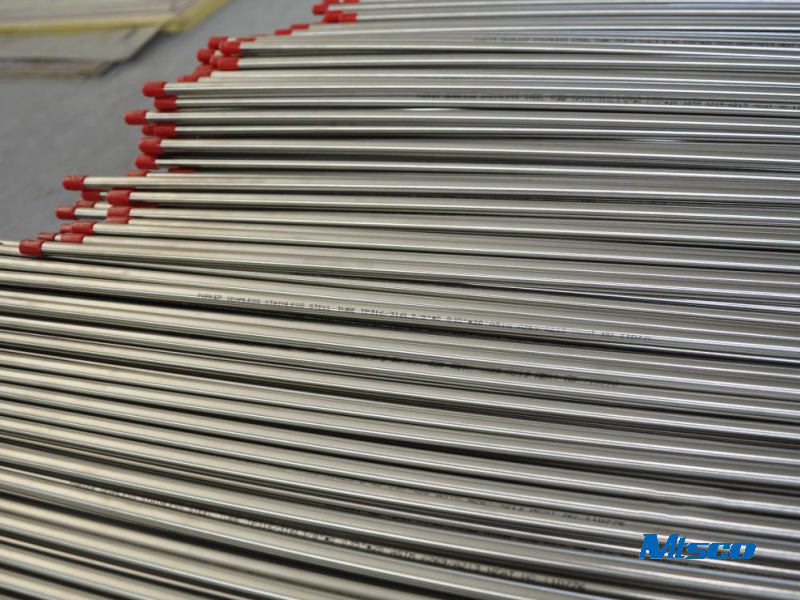

Taw qhia qhov zoo kawg nkaus Nickel Alloy Seamless Tube los ntawm MT Stainless Steel, crafted tshwj xeeb rau cov kev xav tau ntawm kev lag luam tshuaj. Cov khoom no yog ua raws li ASTM B163; ASTM B167; ASTM B444; ASTM B622 tus qauv, kom ntseeg tau qhov zoo tshaj plaws thiab kev nyab xeeb. Peb cov Nickel Alloy Seamless Tube, tsim los ntawm ntau qib UNS suav nrog N10675, N10001, N10665, N10276, N06022, N08800, N08825, N04400, muaj qhov tshwj xeeb tiv thaiv hydrochloric acid ntawm txhua qhov kev siv zog thiab kub. Tsis tas li ntawd, nws zoo tiv taus lwm yam nonoxidizing xov xwm xws li sulfuric, phosphoric, formic, acetic acids, muab kev tiv thaiv zoo heev rau pitting corrosion, kev nyuaj siab corrosion cracking, thiab riam kab thiab weld tshav kub cuam tshuam cheeb tsam nres.Thaum nws los txog rau daim ntawv thov, peb cov Nickel Alloy B. -3 qhia txog kev sib raug zoo nyob qhov twg Alloy B-2 yog qhov tseem ceeb. Thov nco ntsoov tias nws yuav tsum tsis txhob siv nyob rau hauv lub xub ntiag ntawm ferric los yog cupric ntsev raws li qhov no yuav instigate sai corrosion nres.Dab tsi teev MT Stainless hlau sib nrug yog peb stringent zoo tswj. Kev ua tau zoo tau lees paub nrog Daim Ntawv Pov Thawj Zeb Xeem tau muab nrog txhua qhov kev xa khoom thiab kev tshuaj xyuas thib peb yog ib txwm ua tau. Ib sab, peb cov khoom tau raug kuaj nruj xws li Ultrasonic test, Eddy Tam sim no test, Mechanical Test (Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test), thiab Hlau Test (Metallographic Analysis, Impact Test-High/low temperature). Peb qhov kev cog lus rau cov neeg siv khoom txaus siab yog peb qhov tseem ceeb tshaj plaws. Yog nws FOB, CFR, lossis CIF, peb muab cov khoom lag luam hloov tau. Kev them nyiaj tuaj yeem ua los ntawm T / T lossis LC, thiab lub sijhawm xa khoom ntawm 30 hnub ua haujlwm tom qab tau txais koj qhov tso nyiaj tau lees paub. Tsis tas li ntawd, cov ntim khoom raug txiav raws li tus neeg siv khoom nyiam, yog nws lub rooj plaub hlau lossis lub hnab woven. Xaiv kev ntseeg siab, xaiv MT Stainless Steel.

Ntawm MT Stainless Steel, peb txaus siab rau kev xa cov khoom zoo tshaj plaws rau peb cov neeg siv khoom. Peb Nickel Alloy Coiled Tubing yog ib qho pov thawj rau qhov kev cog lus no. Cov khoom lag luam hwm no, tsim nyog rau ntau yam kev siv, tshwj xeeb hauv kev lag luam tshuaj, zoo kawg nkaus hauv kev ruaj khov thiab ruaj khov. Tsim los ntawm ntau qib (UNS N10675, UNS N10001, UNS N10665, UNS N10276, UNS N06022, N08800, N08825, N04400), txhua lub nickel alloy coiled tubing peb tsim kom muaj zog tiv thaiv thiab ntau yam tshuaj tiv thaiv. Lub peev xwm tiv taus cov xwm txheej no ua rau peb cov nickel alloy coiled tubing yog cov khoom lag luam nrhiav hauv kev lag luam chemical.Outer Diameter 3 ntawm peb cov nickel alloy coiled tubing ua kom yooj yim hauv kev tuav thiab optimizing qhov chaw, yog li txhim kho tag nrho kev ua haujlwm. Qhov profile me ntawm cov khoom no tsis cuam tshuam nws lub peev xwm los tiv thaiv kev kub ntxhov, ua rau nws tsis muaj dab tsi luv luv ntawm kev lag luam standout.

Cov Khoom Siv Qib: UNS N10675, UNS N10001, UNS N10665, UNS N10276, UNS N06022, N08800, N08825, N04400; lwm

Sab nraud txoj kab uas hla: 3.18mm-101.6mm

Phab ntsa Thickness: 0.5mm-20mm

Ntev: Feem ntau ruaj ntev 6m, tuaj yeem ua raws li tus neeg siv khoom xav tau

Txuj: ASTM B163; ASTM B167; ASTM B444; ASTM B622 thiab lwm yam

Technology: Cold Drawn / Cold Rolled

Nta:

Nickel Alloy B-3 muaj qhov ua tau zoo heev rau hydrochloric acid ntawm txhua qhov siab thiab kub. Nws kuj tiv taus sulfuric, phosphoric, formic, acetic acids thiab lwm yam nonoxidizing media. Nws muaj kev tiv thaiv zoo heev rau pitting corrosion, kev nyuaj siab corrosion cracking, thiab riam kab thiab weld tshav kub cuam tshuam cheeb tsam nres. Hastelloy B-3 muaj thermal stability ntau dua li Alloy B-2.

Daim ntawv thov:

Alloy B-3 yog tsim rau cov ntawv thov uas yuav tsum tau Alloy B-2. Zoo li Alloy B-2, Alloy B-3 yuav tsum tsis txhob siv nyob rau hauv lub xub ntiag ntawm ferric los yog cupric ntsev vim tias cov ntsev no yuav ua rau corrosion sai sai.

| Cov Cai & Cov Cai | Yam khoom | FOB, CFR, CIF lossis raws li kev sib tham |

| Kev them nyiaj | T / T, LC lossis raws li kev sib tham |

| Lub sij hawm xa tuaj | 30 hnub ua haujlwm tom qab tau txais koj cov nyiaj tso cia (Nquag raws li qhov kev txiav txim kom muaj nuj nqis) |

| Pob | Hlau rooj; woven hnab los yog raws li tus neeg yuav tsum tau muaj |

| Kev Xav Tau Zoo | Mill Test Certificate yuav muab xa nrog cov khoom xa tuaj, Kev Tshawb Fawb Thib Peb tau txais |

| Zoo | Kuaj | NTD (Ultrasonic test, Eddy Tam sim no kuaj); |

| Mechanical Test (Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic Test); |

| Hlau Test (Metallographic Analysis, Impact Test-High/low temperature); |

| Tshuaj ntsuam xyuas (Photoelectric Emission Spectroscopic) |

| Kev ua lag luam | Lub khw loj | Teb chaws Europe, Middle East, Southeast Asia, South America. lwm |

Yav dhau los:Alloy B-2 / UNS N10665 ASTM B622 Nickel Alloy Annealed & Pickling Tube Rau Tshuaj Txheej Txheem Kev Lag LuamTom ntej:Alloy C276 Nickel Alloy Smls Tube Nrog BA / AP Tube ASTM Txuj Rau Kev Pabcuam Roj

Thaum koj xaiv MT Stainless Steel lub nickel alloy coiled tubing, koj tab tom nqis peev rau qhov zoo, kev ntseeg tau, thiab kev ua haujlwm tsis sib xws. Peb nkag siab txog qhov tshwj xeeb xav tau ntawm kev lag luam tshuaj, thiab peb cov khoom tsim los ua kom tau raws li lub taub hau no. Peb txuas ntxiv kho peb cov txheej txheem tsim khoom thiab kev tswj xyuas kom zoo los xyuas kom meej tias peb xa cov khoom zoo ib yam, qib siab uas peb cov neeg tuaj yeem nyob ntawm qhov xaus, peb cov Nickel Alloy Coiled Tubing yog ntau tshaj li cov khoom lag luam; nws yog ib qho kev daws teeb meem uas ua kom muaj kev ua haujlwm zoo ntawm koj txoj kev lag luam. Xaiv MT Stainless Hlau niaj hnub no rau qib siab nickel alloy coiled tubing, cia peb loj hlob koj txoj kev lag luam ua ke.