Hwm Cobalt Alloy Forging: MT Stainless Hlau Nickel Alloy 718 Hlau rau Oilfields

Qib:Alloy 718 / N07718, Alloy 625 / N06625, Alloy 600 / N06600, Alloy 601 / N06601, Alloy C276 / N10276, Alloy 800 / N08800 , Alloy 080 400 , Alloy 080 400

Txuj:ASTM B637; ASTM B166; ASTM B446; ASTM B670; ASTM B335, ASTM B637; ASTM B574; ASTM B408; ASTM B425, thiab lwm yam

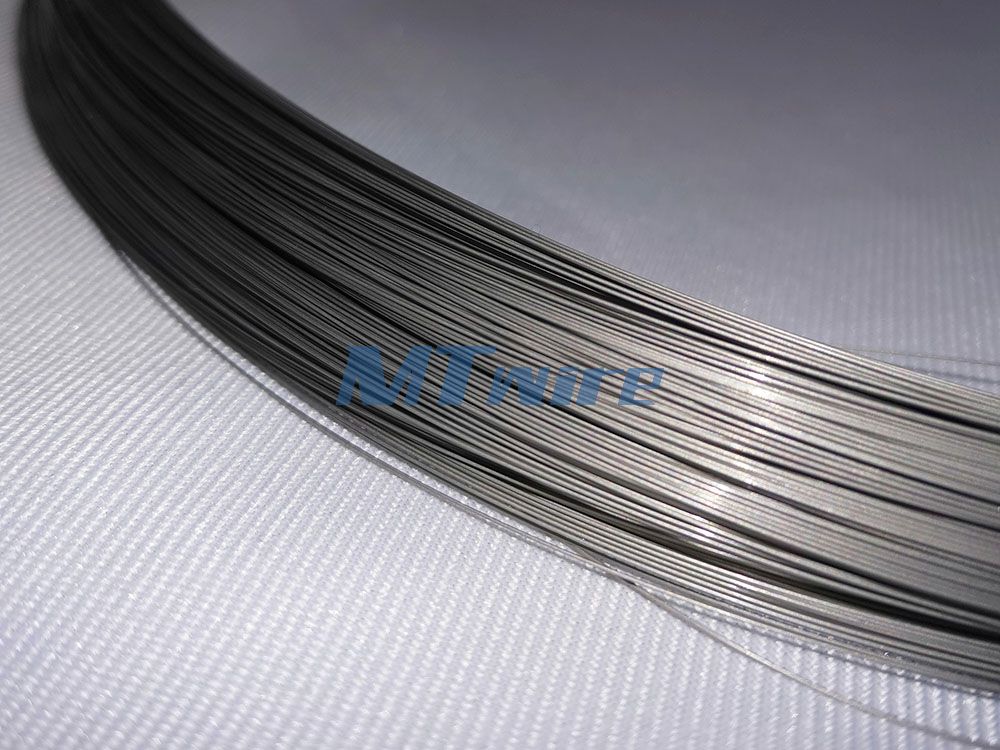

Nto:Bright Annealed / Annealed Pickled

Technology:Txias kos duab

NDT:Ultrasonic kuaj

Kev tshuaj xyuas:100%

Ntim:Pallet / Plywood case / Ntoo Reel

Quality Assurance:ISO & PED

Bar / Rooj | Hlau | |

Sab nraud | ≥10mm | 2mm-5.5 hli |

Length | ≤12000mm | - |

Qhov hnyav | - | ≤350KGS |

Alloy 718 / UNS N07718 Cov tshuaj muaj pes tsawg leeg:

% | Ni | Fe | Cr | Mo | C | Mn | Si | P | S | Co | Nb+Ta | Ti | Al | Cu | B |

min | 50.0 | tshuav nyiaj li cas | 17.0 | 2.80 | - | - | - | - | - | - | 4.75 | 0.65 | 0.20 | - | - |

max | 55.0 | 21.0 | 3.30 | 0.08 | 0.35 | 0.35 | 0.015 | 0.015 | 1.00 | 5.50 | 1.15 | 0.80 | 0.30 | 0.006 |

Lub cev muaj zog:

| Qhov ntom | 8.23 g / cm3 |

| Melting ntau | 1260-1335 ℃ |

Nta: Alloy 718 yog lub hnub nyoog-hardenable npib tsib xee-chromium alloy uas sib txuas corrosion kuj nrog siab zog thiab zoo fabricability. Nws muaj lub zog creep-rupture ntawm qhov kub txog li 700 ℃. Nws zoo heev so kuj pab txhawb rau nws daim ntawv thov nyob rau hauv springs.

Daim ntawv thov: Gas turbine engines, rocket motors, nuclear reactors and spacecraft.

| Cov Cai & Cov Cai | Yam khoom | FOB, CFR, CIF lossis raws li kev sib tham |

| Kev them nyiaj | T / T, LC lossis raws li kev sib tham | |

| Lub sij hawm xa tuaj | 30 hnub ua haujlwm tom qab tau txais koj cov nyiaj tso cia (Nquag raws li qhov kev txiav txim kom muaj nuj nqis) | |

| Pob | Ntoo reel; woven hnab los yog raws li tus neeg yuav tsum tau muaj | |

| Kev Xav Tau Zoo | Mill Test Certificate yuav muab xa nrog cov khoom xa tuaj, Kev Tshawb Fawb Thib Peb tau txais | |

| Zoo | Kuaj | NTD (Ultrasonic test, Eddy Tam sim no kuaj); |

| Mechanical Test (Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic Test); | ||

| Hlau Test (Metallographic Analysis, Impact Test-High/low temperature); | ||

| Tshuaj ntsuam xyuas (Photoelectric Emission Spectroscopic) | ||

| Kev ua lag luam | Lub khw loj | Teb chaws Europe, Middle East, Southeast Asia, South America. lwm |

Yav dhau los:High Quality Nickel Alloy 800/800H Round / Square Bar Raw Khoom Nrog ISO CertificateTom ntej:ASTM B574 Nickel Alloy C22 / UNS N06022 Hlau Nrog Bright Annealed Nto Rau Cov Cuab Yeej Downhole

Peb cov Nickel Alloy 718 Hlau tau dhau los ua cov txheej txheem ntau lawm uas suav nrog Cov Tshuab Txias Kos Duab, uas ua kom lub ntsej muag ci ntsa iab lossis annealed pickled nto. Nrog rau sab nraud txoj kab uas hla ntawm ≥10mm thiab 2mm-5mm xaim, txhua daim hla ntau txheej ntawm kev soj ntsuam, suav nrog kev kuaj Ultrasonic. Qhov no ua kom ntseeg tau tias txhua lub xaim peb xa tawm yog qhov tsis zoo thiab ntawm tus qauv siab tshaj plaws. Ntim yog ib feem tseem ceeb ntawm peb cov txheej txheem thiab. Peb cov khoom xaim tau ntim khoom ruaj ntseg siv pallets, rooj plaub plywood, lossis ntoo reels, lav kev nyab xeeb rau peb cov neeg siv khoom. Kev lees paub zoo yog tsis sib tham ntawm MT Stainless Steel, thiab peb tuav cov lus cog tseg no los ntawm kev ua raws li ISO thiab PED cov qauv nruj me ntsis. Los ntawm kev xaiv peb cov Nickel Alloy 718 Hlau, koj tab tom xaiv cov khoom lag luam uas sawv cev rau tus qauv kub hauv kev lag luam cobalt alloy forging.