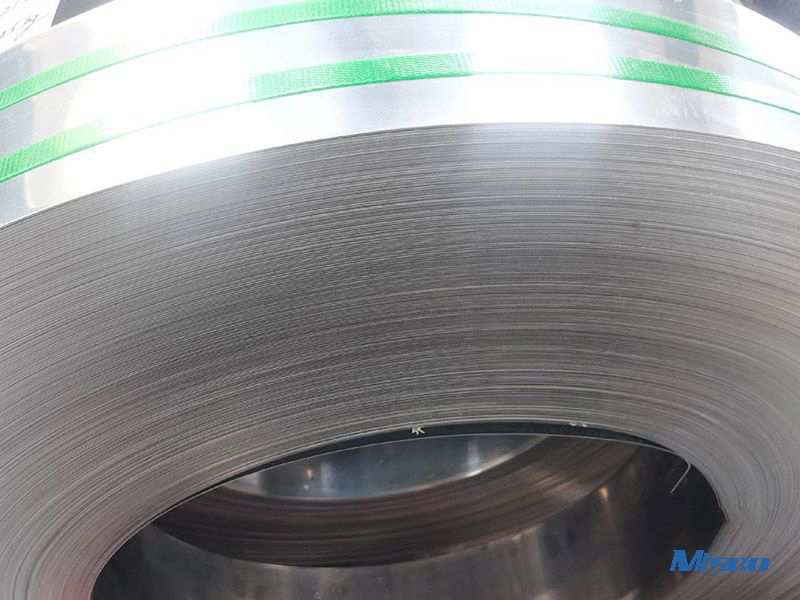

Hwm Zoo Nickel Alloy K500 Strips los ntawm MT Stainless Hlau

Qib: Alloy K500/ N05500, Alloy 625 / N06625, Alloy 600 / N06600, Alloy 601 / N06601, Alloy 718 / N07718, Alloy C276 / N10276, Alloy 800 / N050480, Alloy 800 / 508000 00 ,lwm

Txuj:ASTM B168; ASTM B443; ASTM B670; ASTM B127, ASTM B162; ASTM B333; ASTM B575; ASTM B582; , lwm

Nto:Bright Annealed

Technology:Txias Rolled

NDT:Kev kuaj ultrasonic; Kev xeem Penetrant

Kev tshuaj xyuas:100%

Ntim:Pallet / Plywood case

Quality Assurance:ISO & PED

Daim ntawv | Phaj | Sawb | |

Thickness | 6mm | ≥6mm | 0.15mm-3mm |

Width ua | ≤1200mm | ≤2800mm | ≤1000mm |

Length | ≤3000mm | ≤8000mm | Raws li cov neeg siv khoom xav tau |

Nta:

Alloy K500 / UNS N05500 ua ke Alloy 400 qhov zoo tshaj plaws corrosion kuj nrog ntau zog thiab hardness vim yog ntxiv txhuas thiab titanium thiab kev kho cua sov kom tsim nyog los ua nag lossis daus. Nws yog nonmagnetic ntawm qhov kub thiab txias li -101 ℃. Alloy K500 / UNS N05500 muaj kev ruaj ntseg zoo heev uas muaj txiaj ntsig zoo hauv cov khoom siv siab. Zoo li Alloy 400, nws tsis dhau mus rau qhov hloov pauv mus rau qhov tawg ntawm qhov kub thiab txias li tsawg li cov kua hydrogen. Nws tensile thiab yield zog nce thaum ductility thiab toughness tsuas yog me ntsis impaired.

Daim ntawv thov:

Cov txheej txheem tshuaj twj tso kua mis thiab valve Cheebtsam; ntawv ntau lawm pulp ua kws kho hniav thiab scrapers; marine engineering chains, cables, fasteners thiab springs; cov khoom siv hluav taws xob; thiab roj thiab roj ntau lawm uas tsis yog-sib nqus tsev nyob, twj tso kua mis shafts thiab impellers.

Los ntawm ntau tshaj kaum xyoo ntawm kev tshawb fawb thiab kev tsim kho, kev tsim khoom ntawm MTSCO Alloy thev naus laus zis thiab kev ua haujlwm ntawm ntau yam khoom siv tau zoo heev. Lub tuam txhab tau dhau lub teb chaws kev tswj hwm kev ua haujlwm tau ntawv pov thawj ntawm riam phom thiab khoom siv, tau txais ntau tshaj 24 daim ntawv tso cai patent, koom nrog kev hloov kho ntawm 9 lub teb chaws tus qauv thiab 3 cov qauv kev lag luam. MTSCO tau koom tes nrog kev sib koom ua tub rog hauv kev ua tub rog, muab cov ntaub ntawv kub kub rau PLA chav tsev, muab cov khoom zoo tshwj xeeb alloy rau Tuam Tshoj kev lag luam kev lag luam pab pawg, thiab muab cov khoom siv qis qis tshiab rau Tuam Tshoj aviation kev lag luam. Nws tau ua tiav zoo rau kev siv dav hlau loj hauv tebchaws C919, hloov cov khoom xa tuaj nrog cov neeg tuaj txawv teb chaws, rhuav tshem kev cuam tshuam txawv teb chaws thiab sau cov khoom hauv tsev.

|  |

1. Peb lub tuam txhab tau mob siab rau tsim cov nickel alloy raj txij li xyoo 2011, muaj kev ua tiav kev tsim khoom thiab kev tswj hwm ntau.

2. Peb muaj cov khoom siv NDT siab heev rau cov kev ntsuam xyuas xws li Eddy Tam sim no xeem, Ultrasonic xeem, Hydraulic xeem thiab hais txog.

3. Peb muaj ISO 9001 thiab PED daim ntawv pov thawj, thiab Daim Ntawv Pov Thawj Kev Tshawb Fawb Thib Peb xws li TUV, BV, Lloyd's, SGS, thiab lwm yam, kuj tuaj yeem muab tau raws li cov neeg siv khoom xav tau.

4. Qhov chaw saum npoo yog ib qho ntawm peb qhov zoo tshaj plaws: txhawm rau ua kom tau raws li qhov xav tau sib txawv rau qhov chaw nyob, peb muaj annealing thiab pickling nto, ci annealing nto, polished nto thiab lwm yam.

5. Txhawm rau ua kom lub hauv paus ntawm cov yeeb nkab huv si thiab ua kom tsis txhob muaj qhov deburring, peb lub tuam txhab tsim cov cuab yeej tshwj xeeb thiab tshwj xeeb - Daim txhuam cev ntxuav nrog kev kub siab.

6. Peb muaj kev pabcuam tomqab muag tag los daws cov teeb meem hauv lub sijhawm.

Yav dhau los:Muaj zog Corrosion Resistance Nickel Alloy 825 / UNS N08825 Tswj Kab nrog Hlau Reel rau GeothermTom ntej:Ntshiab Nickel 200 / UNS N02200 Nickel Alloy Sheet / Phaj Melting nrog VIM thiab ESR