Igwe anaghị agba nchara MT: Ngwọta Ngwọta Ngwọta Ngwọta Nickel Alloy Control Line

Ọkwa | Alloy825/N08825, Alloy625/N06625, Alloy400/ N04400, Alloy C276/N10276, 2205, 2507, TP316/L, TP304/L, wdg |

Ụdị | Agbadoro |

Ọnụ oghere | Single/Multi Core |

Dayameta dị n'èzí | 4mm-25mm |

Ọkpụrụkpụ mgbidi | 0.3mm-2.5mm |

Ogologo | Dị ka mkpa ndị ahịa si dị, ruo 10000m |

Ọkọlọtọ | ASTM A269/A213/A789/B704/B163, wdg. |

Asambodo | ISO/CCS/DNV/BV/ABS, wdg. |

Nyocha | NDT; Nnwale Hydrostatic |

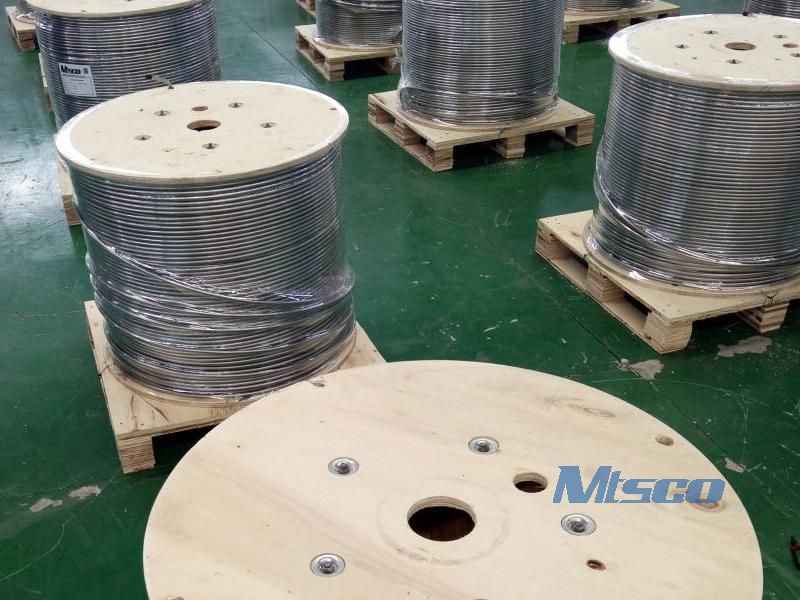

ngwugwu | Osisi ma ọ bụ ígwè |

Ngwa nke tube capillary:

• Jikwaa tubing dị na mmanụ na gas nke ọma

• Ọkụkụ akụrụngwa

• ahịrị tubing injection kemikal

• ahịrị njikwa hydraulic

• ahịrị njikwa okpuru mmiri

• A ahịrị njikwa smoothbore na ngwa fiber optic

|  |

Nickel Alloy8Ngwakọta kemịkalụ 25 Ọkụ Exchange Tube:

| % | Ni | Fe | Cr | C | Mn | Si | S | Mo | Cu | Ti | Al |

| min | 38 | 22 | 19.5 | 2.5 | 1.5 | 0.6 | |||||

| max | 46 | 23.5 | 0.05 | 1 | 0.5 | 0.03 | 3.5 | 3 | 1.2 | 0.2 |

Atụmatụ:Alloy 825 nwere ezigbo nguzogide corrosion nrụrụ nke chloride-ion, na-ebelata gburugburu nwere phosphoric na sulfuric acid, gburugburu oxidizing nwere nitric acid na nitrates, na pitting, crevice corrosion na intergranular corrosion. Ọ nwere ezigbo n'ibu Njirimara na cryogenic okpomọkụ ka moderately elu okpomọkụ ruo 538 ℃.

Ngwa:Ụlọ ọrụ usoro kemịkalụ, mmepụta acid, ngwá ọrụ pickling, ngwá ọrụ nchịkwa mmetọ.

Ọnụ ọgụgụ na-arịwanye elu nke oru ngo na ụlọ ọrụ ọrụ mmanụ chọrọ iji ogologo oge na-aga n'ihunickel alloycapillary tube. A na-eji ha eme ihe n'ụdị dị iche iche, gụnyere ntụtụ kemịkalụ, njikwa hydraulic, umbilical ngwá ọrụ na njikwa mmiri. MTSCO na-enye ngwaahịa maka ngwa ndị a niile, na-enyere ndị ahịa aka ibelata ụgwọ ọrụ ma melite ụzọ mgbake.

MTSCO nwere ike ịnye tubing na-aga n'ihu maka nickel alloy, igwe anaghị agba nchara na tube capillary duplex. Ogo, ogologo, ọkwa nrụgide, ụzọ nkwakọ ngwaahịa, wdg nwere ike ịhazi ya iji melite ụzọ mgbake mmanụ gị ma belata ụgwọ ọrụ.

Nke gara aga:Nickel Alloy 625/UNS N06625 Welded Capillary Tube for Subsea Control LineOsote:Nickel Alloy C276/ UNS N10276 Corrosion Resistance Welded Control Line Tubing maka TEC Cable

Ụdị ngwaahịa anyị gụnyere ma ụdị welded na ndị nwere oghere dị iche iche, site na otu ruo ọtụtụ isi. Anyị na-enye ndị ahịa anyị nhọrọ nwere ike ịhazi ya na dayameta mpụta nke 4mm-25mm na ọkpụrụkpụ mgbidi efu. Nke a buru ibu di iche iche ana achi achi ndakọrịta na a dịgasị iche iche nke ngwa eletrọnịkị, otú, na-enyere gị aka nweta elu arụpụta oge ọ bụla. Na MT igwe anaghị agba nchara, anyị na-agba mbọ maka ịdị mma n'akụkụ ọ bụla nke azụmahịa anyị - site na imepụta na imepụta tubing akara nickel alloy ruo na ọrụ ndị ahịa zuru oke ma na-anabata ya. Ndị ọkachamara anyị nwere ahụmahụ nwere ihe ọmụma na nkà iji nyere gị aka ịhọrọ ngwaahịa ziri ezi maka mkpa gị. Nweta ihe dị iche MT igwe anaghị agba nchara taa site na ngwọta tubing njikwa nickel alloy dị elu.