MT Hastelloy Tube: High-Quality Alloy 825/625 Inner Tube for Oil and Gas Downhole Cables

kel Alloy Inner Tube for Hybrid Downhole Cable, Alloy 825/625 Oil and Gas

| Fiber cores | 1~4 cores |

| Conductor structure | multiple copper wires twisted |

| Insulation | PP/FEP |

| Grade of steel tube | 316L, A825, A625 |

| Temperature class | 80℃、150℃、200℃,etc |

| Type | Concentric |

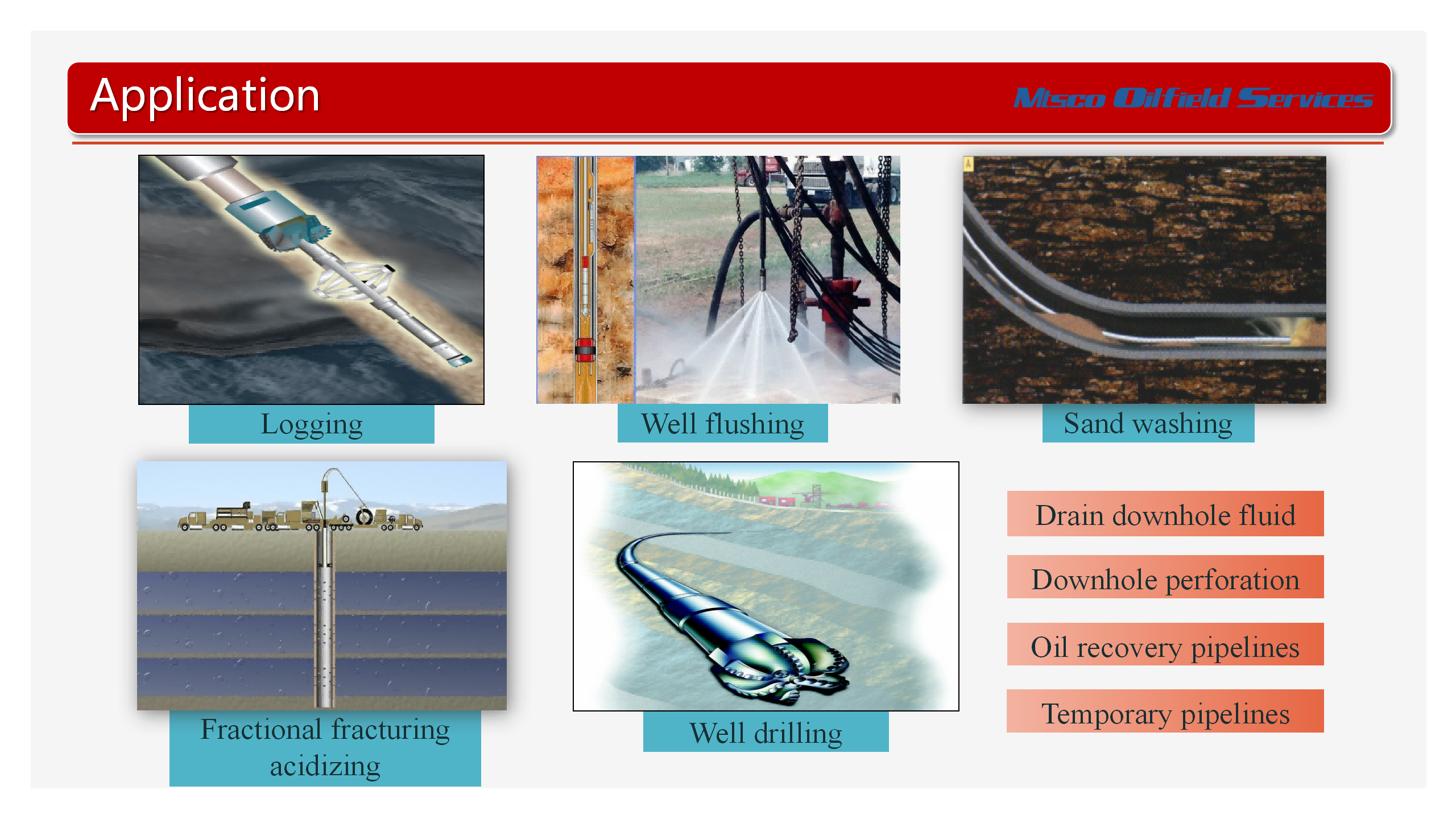

MTSCO cables are used to transmit signals, monitor and supply power in downhole applications where various downhole production data needs to be collected and channels established with the formation during oil and gas production. For the tubing, we mainly supply materials of stainless steel, duplex steel and nickel alloy (such as 304/L,316/L, 2205, 2507,alloy 625, alloy 825). Diameters from 4mm to 88.9mm and our length can be up to 33000ft (10000m).

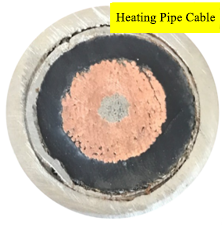

And MTSCO can supply cables of fiber cable, composite cable, logging cable and heating cable. For oil and gas wells that have experienced production declines or shutdowns due to fluid accumulation, fouling, waxing, or corrosion, MTSCO cables can be targeted to help you solve the problem.

|  |

Nickel Alloy 825 Heat Exchange Tube Chemical composition:

| % | Ni | Fe | Cr | C | Mn | Si | S | Mo | Cu | Ti | Al |

| min | 38 | 22 | 19.5 | 2.5 | 1.5 | 0.6 | |||||

| max | 46 | 23.5 | 0.05 | 1 | 0.5 | 0.03 | 3.5 | 3 | 1.2 | 0.2 |

Features: Alloy 825 has excellent resistance to chloride-ion-induced stress corrosion cracking, reducing environments containing phosphoric and sulfuric acids, oxidizing environments containing nitric acid and nitrates, and pitting, crevice corrosion and intergranular corrosion. It has good mechanical properties at cryogenic temperatures to moderately high temperatures up to 538℃.

Applications: Chemical process industry, acid production, pickling equipment, pollution control equipment.

Previous:Oil Drilling Heating Cable UNS N06625 Nickel Alloy Tube Outer TubingNext:Fiber Cable with Nickel Alloy Inner Tube Alloy 600/625 for Downhole Tools

Our product is distinguished by its concentric design and is available in temperature classes of 80℃, 150℃, and 200℃, catering to a broad range of operational demands. The MT Hastelloy Tube is not just a product; it is an indispensable part of your oil and gas operations. With it, you can ensure that your downhole applications run smoothly, providing you with critical data when you need it most. In choosing the MT Hastelloy Tube, you are investing in a product of innovation and resilience - a product that showcases the MT Stainless Steel commitment to quality and robust engineering. This is more than just an inner tube for your hybrid downhole cables - it is a tool for optimization, efficiency, and reliability in your oil and gas production endeavors. Choose MT Hastelloy Tube for a truly superior solution in downhole applications.