MT Stainless Steel: Alloy 200/201 Pure Nickel Wire and Bar for Downhole Tools

Grade: Alloy 200/ N02200, Alloy 201/ N02201, Alloy 625 /N06625 , Alloy 600 /N06600 ,Alloy 601 /N06601 , Alloy 718 /N07718, Alloy C276 /N10276 , Alloy 800 /N08800 , Alloy 825 /N08825 , Alloy 400 /N04400,etc

Standard: ASTM B166; ASTM B446; ASTM B670; ASTM B335;ASTM B637; ASTM B574; ASTM B408; ASTM B425 , etc

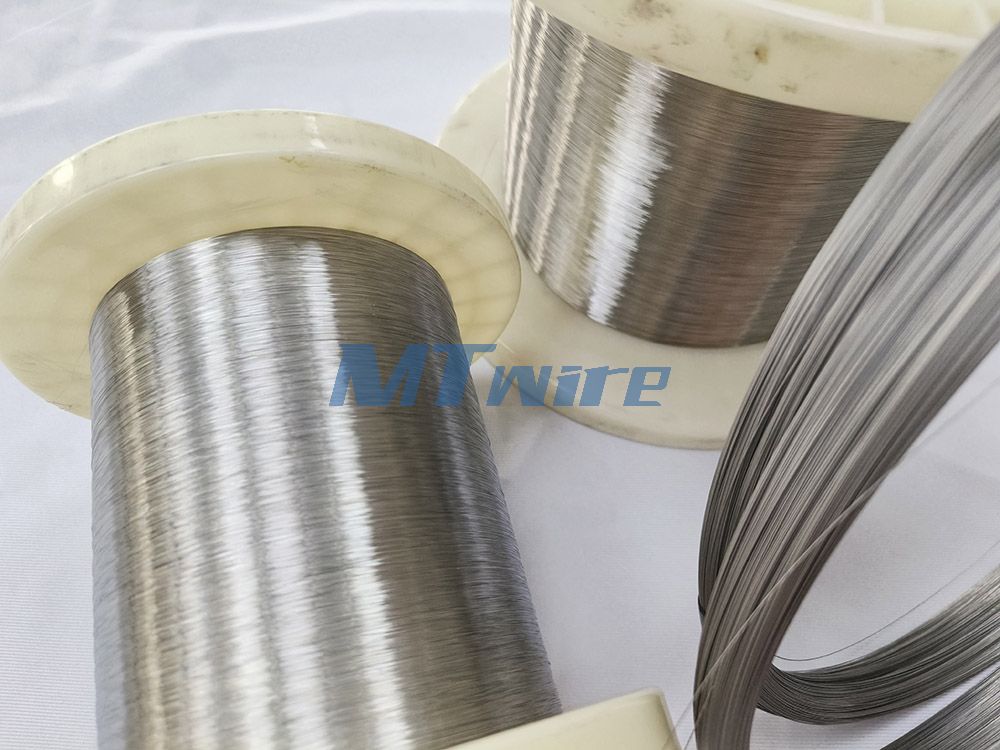

Surface: Bright Annealed/ Annealed Pickled

Technology: Cold Drawing

NDT: Ultrasonic test

Inspection: 100%

Packing: Pallet/ Plywooden case/ Wooden Reel

Quality Assurance: ISO & PED

Bar/ Rod | Wire | |

Outer Diameter | ≥10mm | 2mm-5.5mm |

Length | ≤12000mm | - |

Weight | - | ≤350KGS |

Features: Nickel 200 is commercially pure wrought nickel. It is highly resistant to various reducing chemicals. It can also be used in oxidizing conditions that cause the formation of a passive oxide film, for instance its unexcelled resistance to caustic alkalis. Nickel 200 is limited to service at temperatures below 315℃, because at higher temperatures it suffers from graphitization which results in severely compromised properties. In that circumstance, Nickel 201 is used instead. It has a high Curie temperature and good magnetostrictive properties. Its thermal and electrical conductivities are higher than nickel alloys.

Nickel 201 is the low-carbon version of Nickel 200. Because of its low carbon content, Nickel 201 is not subject to embrittlement by intergranularly precipitated carbon or graphite when exposed to temperatures of 315 to 760℃ for prolonged time if carbonaceous materials are not in contact with it. Therefore, it is a substitute for Nickel 200 in Applications above 315℃. However it does suffer from intergranular embrittlement by sulfur compounds at temperatures above 315℃. Sodium peroxide can be used to change them to sulfates to counteract their effect.

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

| Package | Wooden reel; woven bag or as per customer’s requirement | |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

| Quality | Test | NTD(Ultrasonic test, Eddy Current test); |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test); | ||

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature); | ||

| Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Previous:Nickel Alloy 600/601 Wire With BA/AP Surface For Chemical Injection LineNext:ASTM B446 Nickel Alloy 625/UNS N06625 Wire 2mm For Oilfield Service