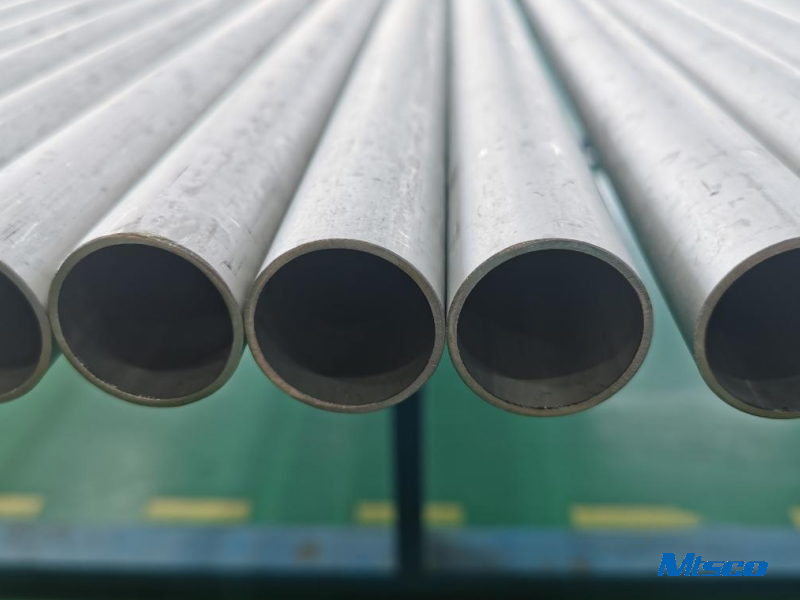

MT Stainless Steel: Manufacturers of Alloy 400 Seamless Nickel Pipes for Geotherm Applications

Geotherm Used Nickel Alloy Pipe UNS N04400 Seamless Pipe With PED

Material:UNS N04400

Standard: ASTM B161/163, ASTM B 168/B 906

Outer Diameter: 6mm-457mm

Wall Thickness: 0.75mm-20.00mm

Surface: Annealed &Pickling

Technology:Cold Drawn / Cold Rolled

NDT:Eddy Current Or Hydraulic Test

Inspection:100%

Packing:Plywooden case or Bundle

Quality Assurance:ISO & PED & AD2000

Type:Seamless&Welded

Nickel Alloy 400 Chemical Composition:

% | Ni | Cu | Fe | C | Mn | Si | S |

min | 63 | 28 | |||||

max | 34 | 2.5 | 0.3 | 2 | 0.5 | 0.024 |

Nickel Alloy 400 Physical properties

Density | 8.80 g/cm3 |

Melting range | 1300-1350℃ |

|  |

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

| Package | Iron case; woven bag or as per customer’s requirement | |

| Quality | Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

| Test | NTD(Ultrasonic test, Eddy Current test) | |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test) | ||

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature) | ||

| Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Features: Nickel alloy 400 has excellent resistance to corrosion by many reducing media such as sulfuric and hydrochloric acids. It is generally more resistant to corrosion by oxidizing media than higher copper alloys. Monel 400 resists pitting and stress corrosion cracking in most fresh and industrial waters. It has good resistance in flowing seawater, but under stagnant conditions, pitting and crevice corrosion is induced. Alloy 400 is probably the most resistant to hydrofluoric acid in all concentrations up to the boiling point, of all engineering alloys. Alloy 400 is notable for its toughness, it does not show embrittlement tendency at cryogenic temperatures. It is work hardenable.

Applications: Chemical process equipment, crude oil stills, gasoline and fresh water tanks, marine engineering equipment, valves, pumps and fasteners.

Previous:UNS N06600 Nickel Alloy Seamless AP Pipe For FertilizerNext:Oil Drilling Heating Cable UNS N06625 Nickel Alloy Tube Outer Tubing