Introducing the Alloy 601 / UNS N06601 Seamless Nickel Alloy Tube from MT Stainless Steel - your trusted supplier and manufacturer. This product is not just a tube, but an embodiment of durability and efficiency, specifically engineered for the heat exchanger and oilfield downhole industries.

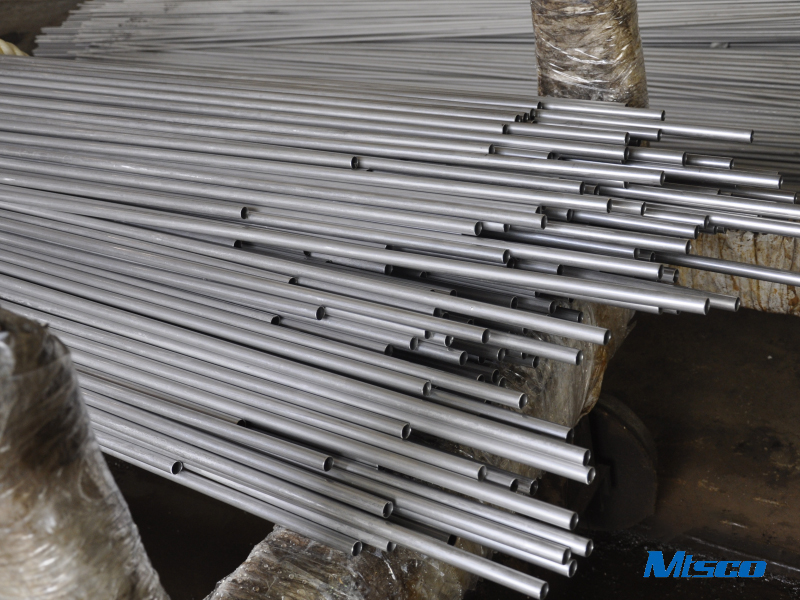

Constructed from Materials: UNS N06601, our product meets ASTM B829 ASTM B 168/B 906 standards, guaranteeing quality and reliability. With an outer diameter of 6mm-355.60mm and wall thickness of 1.00mm-20.00mm, this tube is designed to withstand high pressure and intense conditions. Its brilliant annealed surface and cold drawn/ cold rolled technology afford it superior strength and fabricability.

One of the Alloy 601 Tube's significant advantages is its superior resistance to heat and corrosion, especially exceptional at elevated temperatures up to 1200℃. The product's high strength and resistance to aqueous corrosion make it an unmissable asset in various applications such as the chemical process industry, waste incinerators, power generation equipment, heat treating equipment, and gas turbine engine components.

MT Stainless Steel ensures 100% inspection and quality assurance of each product as per ISO & PED & AD2000 standards. We utilize advanced non-destructive testing methods such as Eddy Current or Hydraulic Test for maximum precision.

MT Stainless Steel's commitment to excellence extends to our packaging as well; our Alloy 601 tubes are securely packed in plywooden cases or bundles to ensure safe delivery.

Trust MT Stainless Steel for unbeatable Inconel 601 and seamless Nickel Alloy Tubes, offering superior performance and long-lasting service.

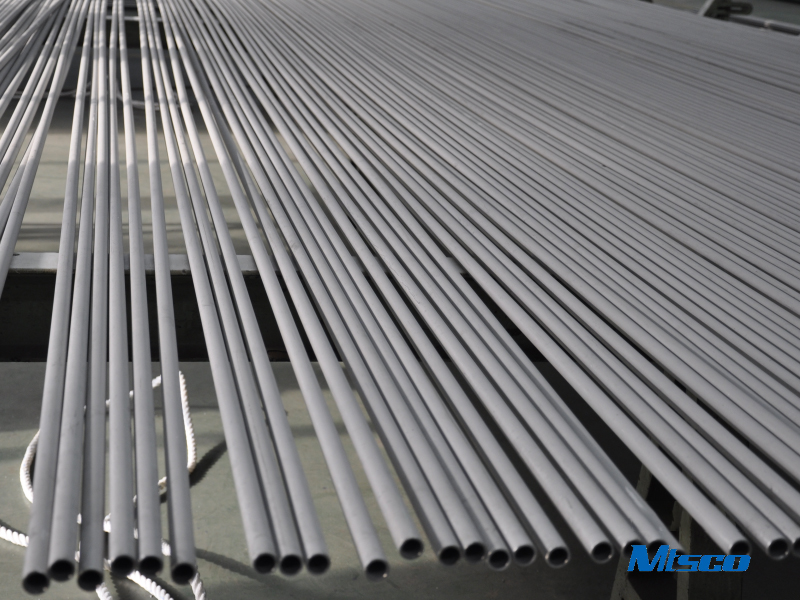

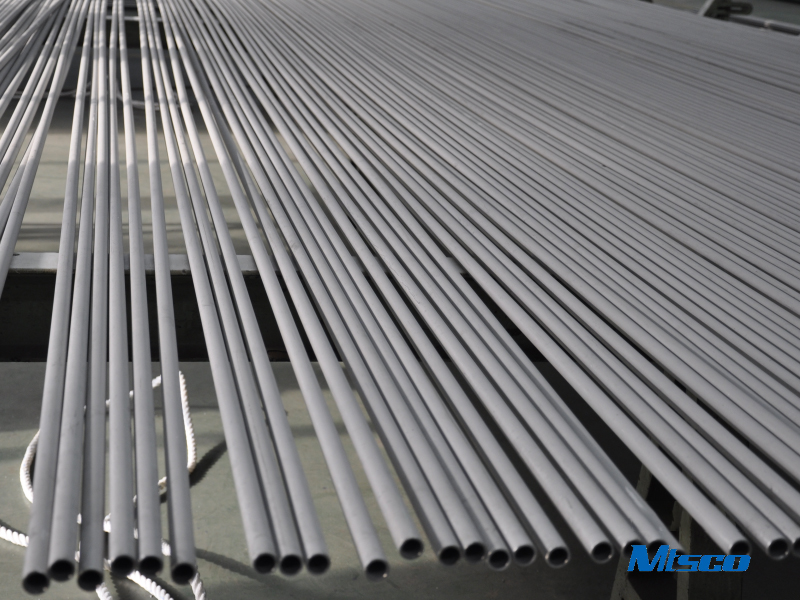

Introducing MT Stainless Steel's premium Capillary Tube, an unrivaled solution for heat exchange and oilfield applications. Meticulously crafted from Alloy 601, our capillary tube has become the industry standard for exceptional quality and durability.

The material used is UNS N06601, renowned for its strength and resistance to oxidation at high temperatures. The uniqueness of this material is its ability to retain a stable, austenitic structure during prolonged exposure to high temperatures. This feature distinguishes our capillary tube as the preferred choice for heat exchange applications across a multitude of sectors, including oil and gas, petrochemicals, and power generation industries.

Compliance with international norms is a hallmark of MT Stainless Steel's commitment to quality, and our capillary tube is no exception. Adhering to ASTM B829 and ASTM B 168/B 906 standards, these tubes meet the most stringent specifications for mechanical properties, chemical composition, and surface finish.

Our capillary tube's superior construction is apparent right down to the dimensions. With an outer diameter ranging from 6mm to 355mm, we cater to diverse industry requirements, from precision instruments to heavy-duty equipment. The versatility of our tube’s dimensions enhances its adaptability, making it compatible with almost any system.

Material:UNS N06601

Standard: ASTM B829 ASTM B 168/B 906

Outer Diameter: 6mm-355.60mm

Wall Thickness: 1.00mm-20.00mm

Surface:Bright Annealed

Technology:Cold Drawn / Cold Rolled

NDT:Eddy Current Or Hydraulic Test

Inspection:100%

Packing:Plywooden case or Bundle

Quality Assurance:ISO & PED & AD2000

Type:Seamless&Welded

Chemical composition

| % | Ni | Cr | Fe | C | Mn | Si | S | Al | Cu |

| min | 58.0 | 21.0 | balance | | | | | 1.00 | |

| max | 63.0 | 25.0 | 0.10 | 1.00 | 0.50 | 0.015 | 1.70 | 1.00 |

Physical properties

| Density | 8.11 g/cm3 |

| Melting range | 1360-1411℃ |

Features: UNS N06601 has good resistance to heat and corrosion, especially outstanding to oxidation at elevated temperatures up to 1200℃. It also has high strength, good fabricability and good resistance to aqueous corrosion.

Applications: Chemical process industry, waste incinerators, power generation equipment, heat treating equipment, and gas turbine engine components.

Stanard Wire Gauge ( Fomerly Imperial Wire Gauge ) SWG |

SWG | Wall Thickness | SWG | Wall Thickness |

0 | 0.324 | 8.23 | 21 | 0.032 | 0.81 |

1 | 0.3 | 7.62 | 22 | 0.028 | 0.71 |

2 | 0.276 | 7.01 | 23 | 0.024 | 0.61 |

3 | 0.252 | 6.4 | 24 | 0.022 | 0.56 |

4 | 0.232 | 5.89 | 25 | 0.02 | 0.51 |

5 | 0.212 | 5.38 | 26 | 0.018 | 0.46 |

6 | 0.192 | 4.88 | 27 | 0.0164 | 0.42 |

7 | 0.176 | 4.47 | 28 | 0.0148 | 0.38 |

8 | 0.16 | 4.06 | 29 | 0.0136 | 0.35 |

9 | 0.144 | 3.66 | 30 | 0.0124 | 0.31 |

10 | 0.128 | 3.25 | 31 | 0.0116 | 0.29 |

11 | 0.116 | 2.95 | 32 | 0.0108 | 0.27 |

12 | 0.104 | 2.64 | 33 | 0.01 | 0.25 |

13 | 0.092 | 2.34 | 34 | 0.0092 | 0.23 |

14 | 0.08 | 2.03 | 35 | 0.0084 | 0.21 |

15 | 0.072 | 1.83 | 36 | 0.0076 | 0.19 |

16 | 0.064 | 1.63 | 37 | 0.0068 | 0.17 |

17 | 0.056 | 1.42 | 38 | 0.006 | 0.15 |

18 | 0.048 | 1.22 | 39 | 0.0052 | 0.13 |

19 | 0.04 | 1.02 | 40 | 0.0048 | 0.12 |

20 | 0.036 | 0.91 | | | |

Previous:PriceList for Alloy 400 Seamless Pipe - Nickel Alloy C22 / UNS N06022 Pipe ASTM B622 For Shipping Industry With PED/ISO – EraumNext:ASTM B167 Alloy 600/UNS N06600 Nickel Alloy BA/AP Tube For Heat Exchanger

MT Stainless Steel's capillary tube is a testament to our unwavering commitment to delivering high-quality products that offer unrivaled performance. Each tube undergoes rigorous testing and quality control measures to ensure they live up to their industry-leading reputation.

Unleash the power of MT Stainless Steel's capillary tube, the ultimate solution for heat exchange and oilfield applications. Experience the difference that decades of expertise and dedication to quality can make in your industry operations. Experience the MT Stainless Steel's capillary tube difference. Explore unparalleled quality and performance tailor-made for your industry's most demanding applications. With MT Stainless Steel, you're not just investing in a product; you're investing in a legacy of excellence and a future of uncompromised performance.