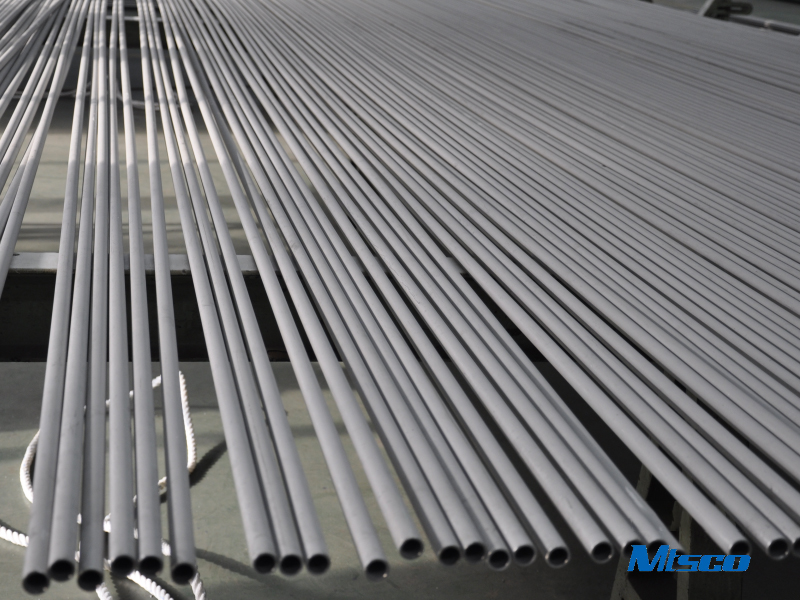

Upgrade your industrial operations with our top-of-the-line Alloy 925 and 926 Nickel Seamless Tubes, specifically designed by MT Stainless Steel to meet your gas down-hole requirements.

As a market-leading manufacturer and supplier, MT Stainless Steel prides itself on offering products that are compliant with ASTM B677, B167, B444, and B622 standards. The alloy 925 and 926 tubes are made from high-quality nickel alloys (UNS N09925, UNS N08926, UNS N06625, UNS N06600, UNS N06601, UNS N10276, UNS N08800, UNS N08825, UNS N04400), ensuring excellent corrosion resistance and structural integrity.

The tubes range in outer diameter from 6.35mm to 355.6mm, with wall thickness varying from 1.65mm to 20.00mm. We offer customizable lengths tailored to your specific needs. As an ISO 9001 and PED certified company, we provide not only superior products but also comprehensive after-sale service to address any concerns.

Our tubes stand out due to their impeccable surface conditions – choose from annealing and pickling, bright annealing, or polished surfaces. We have developed a unique Sponge Washing technology that ensures the tube's inner surfaces are clean and free from deburring.

MT Stainless Steel has mastered the skill of producing nickel alloy tubes since 2011, leveraging advanced NDT equipment for tests such as Eddy Current test, Ultrasonic test, Hydraulic test, and more. Trust in our expertise and experience for seamless integration of our alloy 925 and 926 tubes into your operations. Own the advantage with MT Stainless Steel!

Here at MT Stainless Steel, we are proud to present our top-tier Incoloy tube, a seamless fusion of Alloy 925/926. Our Incoloy tubes are not just a product, but a testament to our commitment to delivering superior quality and performance.

These tubes are constructed from high-grade materials, including the unique blend of UNS N09925, UNS N08926, UNS N06625, UNS N06600, UNS N06601, UNS N10276, UNS N08800, UNS N08825, and UNS N04400. This potent combination creates an Incoloy tube that outstrips standard tubes in durability, longevity, and resilience. With an outer diameter of 6, these tubes are designed to fit seamlessly into their designated applications.

Our Incoloy tubes are renowned for their adaptability and toughness, qualities that make them well-suited for a multitude of industrial applications. These include, but are not limited to, chemical processing, oil and gas extraction, power generation, and more. Their resistance to corrosion, heat, and pressure ensures a longer lifespan and a higher performance level, minimizing the risk of tube failure and subsequent downtimes.

Material Grade: UNS N09925, UNS N08926, UNS N06625, UNS N06600, UNS N06601, UNS N10276, UNS N08800, UNS N08825, UNS N04400; etc

Outer Diameter: 6.35mm-355.6mm

Wall Thickness: 1.65mm-20.00mm

Length: Normally fixed length 6m, can as per customer’s requirement

Standard: ASTM B677; ASTM B167; ASTM B444; ASTM B622 etc.

1 . Our company has been dedicated to producing nickel alloy tube since 2011 , owning complete producing technology and abundant managing experience .

2 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

3 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , Lloyd’s , SGS , etc , also can be provided according to customers’ requirements .

4 . The surface condition is one of our main advantages : in order to meet different requirements for surface condition , we have annealing and pickling surface , bright annealing surface , polished surface etc .

5 . In order to keep the inside surface of pipe clean and make it free from deburring , our company develops the unique and special technology — Sponge Washing with high pressure .

6 . We have complete after-sale service to deal with the problems in time.

Alloy 925 Chemical composition:

% | Ni | Fe | Cr | C | Mn | Si | P | S | Mo | Cu | Ti | Al | Nb |

min | 42.0 | 22.0 | 19.5 | | | | | | 2.5 | 1.5 | 1.9 | 0.10 | |

max | 46.0 | | 22.5 | 0.030 | 1.00 | 0.50 | 0.030 | 0.030 | 3.5 | 3.0 | 2.4 | 0.50 | 0.50 |

Alloy 925 Physical properties

| Density | 8.08 g/cm3 |

| Melting range | 1311-1366℃ |

Previous:Nickel Alloy 825/ N08825 Heat Exchanger Tube For Chemical Equipment With BA/AP SurfaceNext:Alloy B / UNS N10001 ASTM Standard Nickel Alloy Tube Seamless For Oil Industry

At the same time, we understand the importance of environmental responsibility. Therefore, our Incoloy tubes are crafted in a way that minimizes wastage and takes full advantage of the outstanding properties of Alloy 925/926.

In conclusion, MT Stainless Steel's Incoloy tubes represent a formidable balance of innovation, quality, and value. These tubes are not just a product but a promise - a promise of uncompromising quality and class-leading performance. When you choose MT Stainless Steel, you're choosing a blend of engineering excellence and sustainable practices. Choose our Incoloy tubes, and experience the MT Stainless Steel difference today.