MT Stainless Steel's Nickel Alloy 825 Coiled Tubing for Oil and Gas Industry

Grade | Alloy825/N08825, Alloy625 /N06625, Alloy400/ N04400, 2205, 2507, TP316/L, TP304/L, etc |

Type | Welded |

Hole count | Single/Multi Core |

Outer Diameter | 4mm-25mm |

Wall Thickness | 0.3mm-2.5mm |

Length | According to customers’ needs, up to 10000m |

Standard | ASTM A269/A213/A789/B704/B163,etc. |

Certificate | ISO/CCS/DNV/BV/ABS, etc. |

Inspection | NDT; Hydrostatic test |

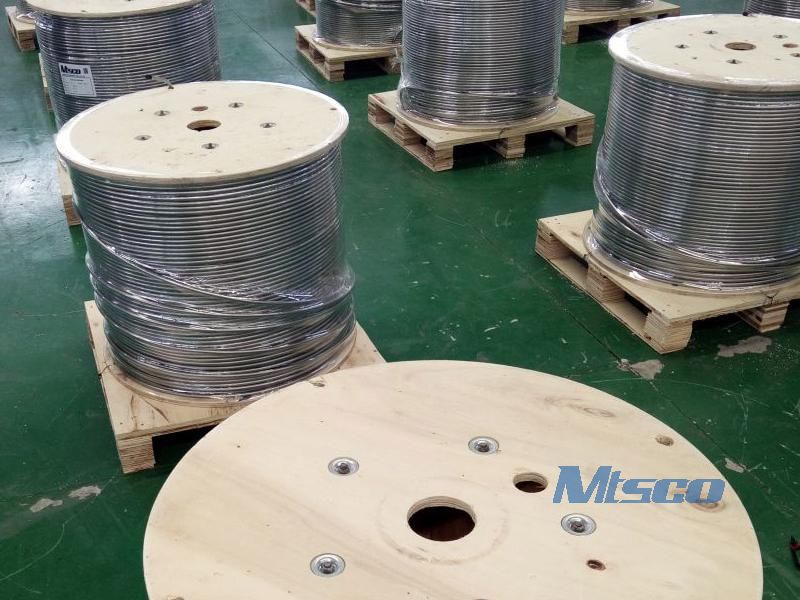

Package | Wooden or iron reel |

Applications of capillary tube:

• Control tubing in oil and gas well

• Instrument tubing

• Chemicl injection tubing line

• Hydraulic control lines

• Subsea control lines

• Smoothbore control lines in fibre optic applications

Nickel Alloy 825 Chemical composition:

| % | Ni | Fe | Cr | C | Mn | Si | S | Mo | Cu | Ti | Al |

| min | 38 | 22 | 19.5 | 2.5 | 1.5 | 0.6 | |||||

| max | 46 | 23.5 | 0.05 | 1 | 0.5 | 0.03 | 3.5 | 3 | 1.2 | 0.2 |

Features: Alloy 825 has excellent resistance to chloride-ion-induced stress corrosion cracking, reducing environments containing phosphoric and sulfuric acids, oxidizing environments containing nitric acid and nitrates, and pitting, crevice corrosion and intergranular corrosion. It has good mechanical properties at cryogenic temperatures to moderately high temperatures up to 538℃.

Applications: Chemical process industry, acid production, pickling equipment, pollution control equipment.

An increasing number of projects in the oil service industry require the use of continuous lengths of nickel alloy capillary tube. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex capillary tube. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.

Previous:Hydraulic Instrument Tubing Nickel Alloy 625/UNS N06625 For Control Lines With DNV CertificateNext:Downhole Tools ASTM B704 Nickel Alloy 625/UNS N06625 Chemical Injection Line for Control Line