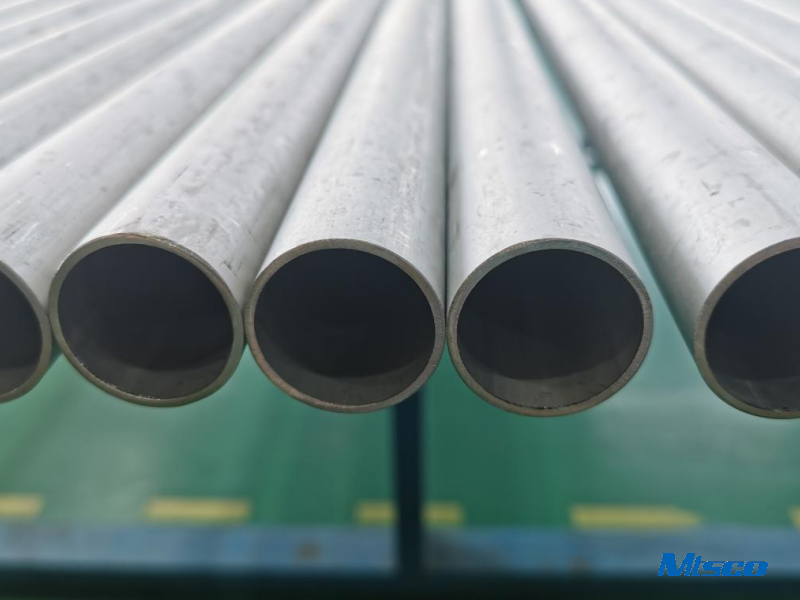

MT Stainless Steel's Nickel Alloy B-2 Seamless Pipe, UNS N10665 for Chemical Industries

MT Stainless Steel presents the cutting-edge Nickel Alloy B-2 seamless pipe, made specifically for the chemical process industry. This superior grade pipe, coded as UNS N10665, is strikingly resistant to various concentrations and temperatures of hydrochloric acid, making it an ideal choice for challenging industrial environments. Along with hydrochloric acid, it also holds its ground against reducing environments such as sulfuric, phosphoric, and acetic acids. This standout feature ushers in a new era of durability and strength.

In addition to its exceptional resistance to different acids, our Nickel Alloy B-2 pipe has excellent resistance to pitting corrosion, stress corrosion cracking, and knife line and weld heat-affected zone attack. This attribute ensures the product's longevity and continuous high performance, even under demanding conditions.

However, Nickel Alloy B-2 has poor resistance to oxidizing environments. Therefore, it should not be used where ferric or cupric salts are present as these salts may cause rapid corrosion failure.

At MT Stainless Steel, we strive to provide solutions that cater to the specific needs of the competitive chemical industry. With our Nickel Alloy B-2 Seamless pipe, we assure you of a product that withstands reducing chemical environments and meets the high standard of ASTM B622.

Our products are created not only to meet but exceed industry standards. We adopt cold drawn or cold-rolled process methods for manufacturing, ensuring high-quality and precision in each product. Trust MT Stainless Steel for all your nickel alloy pipe needs for a seamless integration into your operations.

Previous:Oilfield Service Alloy B / UNS N10001 ASTM Standard Nickel Alloy Pipe With Annealed & Pickling SurfaceNext:Nickel Alloy B-3 / UNS N10675 Pipe With Shot Peening For Chemical Industry

| Item | Description | |

| Basic Information | Material Grade | UNS N10665, N06625, N06600, N06601,N07718, N10276, N08800, N08825, N04400; etc |

| Outer Diameter | 17.1mm-219.1mm | |

| Wall Thickness | 1.65mm-20.00mm | |

| Length | Normally fixed length 6m, can as per customer’s requirement | |

| Standard | ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc | |

| Process Method | Cold Drawn or Cold Rolled | |

| Industry & Advantage | Application | Industrial furnaces, and gas turbine engine seal rings. |

| Advantages | Alloy B-2 has outstanding resistance to hydrochloric acid at all concentrations and temperatures. It also has significant resistance to reducing environments like sulfuric, phosphoric, acetic acids and other nonoxidizing media. Alloy B-2 has excellent resistance to pitting corrosion, stress corrosion cracking, and knife line and weld heat-affected zone attack. | |

Features:

Alloy B-2 has outstanding resistance to hydrochloric acid at all concentrations and temperatures. It also has significant resistance to reducing environments like sulfuric, phosphoric, acetic acids and other nonoxidizing media. Alloy B-2 has excellent resistance to pitting corrosion, stress corrosion cracking, and knife line and weld heat-affected zone attack. Alloy B-2 has poor resistance to oxidizing environments, therefore, it should not be used where ferric or cupric salts are present as these salts may cause rapid corrosion failure.

Applications:

Equipment handling reducing chemical environments; and chemical process industry involving hydrochloric, sulfuric, phosphoric and acetic acids.

|  |

Previous:Oilfield Service Alloy B / UNS N10001 ASTM Standard Nickel Alloy Pipe With Annealed & Pickling SurfaceNext:Nickel Alloy B-3 / UNS N10675 Pipe With Shot Peening For Chemical Industry