Presenting the versatile and robust Nickel Alloy C22 Seamless Tubes, brought to you by MT Stainless Steel, the leading supplier and manufacturer in seamless tube technology. Our product, designed to meet ASTM B622 standards, excels with superior corrosion resistance outperforming Alloy C-276, Alloy C-4, and Alloy 625. This has been achieved by incorporating Ni-Cr-Mo-W alloys, providing exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking.

Our Nickel Alloy C22 tube is built to withstand oxidizing aqueous media, including wet chlorine and mixtures containing nitric acid or oxidizing acids with chloride ions. It is perfectly suited to endure both reducing and oxidizing conditions encountered in process streams, making it the ideal choice for facilities prone to “upset” conditions or multi-purpose plants.

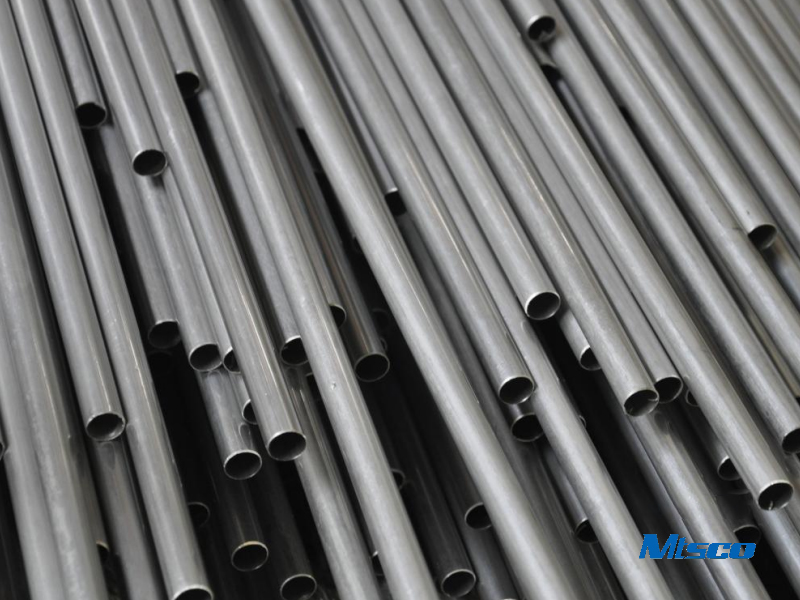

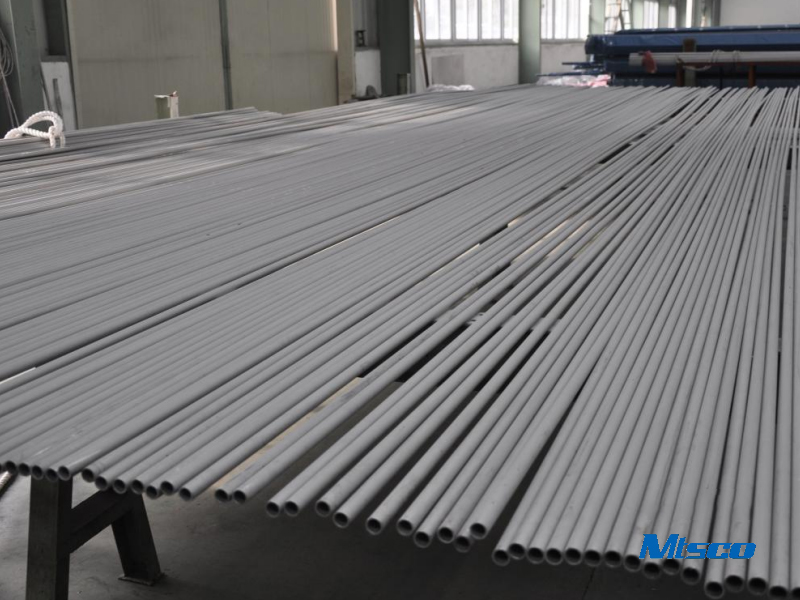

With an Outer Diameter (OD) ranging from 6.35mm to 114.3mm and Wall Thickness (WT) from 1.65mm to 20mm, our Alloy C22 tubes can be customized to suit specific customer needs. Recognized by industry standards like ASTM B163, ASTM B167, ASTM B444, and ASTM B622, our tubes are Cold Drawn/Cold Rolled for maximum precision.

These tubes carve a niche in multiple applications such as heat exchangers, condensers, shipping industry, precision machinery, mechanical structure industry, thermocouples, and cables, amongst others.

Make no compromise on quality, choose MT Stainless Steel’s Nickel Alloy C22 Seamless Tubes for top-notch performance and unmatched durability. Step into the future of seamless tubing technology, experience excellence with MT Stainless Steel.

MT Stainless Steel is proud to introduce one of our flagship products, the Alloy 400 Tube. It's a seamless, custom-made tube that meets the ASTM B622 Standard, highlighting our commitment to top-notch quality and technical excellence. Our Alloy 400 Tube is much more versatile than any other nickel-chrome-molybdenum-tungsten alloy available on the market.

The Alloy 400 Tube outshines comparable alloys, such as Alloy C-276, Alloy C-4, and Alloy 625, particularly with its superior corrosion resistance performance. This is achieved with our careful selection of materials and state-of-the-art manufacturing techniques.

At MT Stainless Steel, we understand the need for durable and efficient materials, hence why we have put so much attention into creating our Alloy 400 Tube, offering an unmatched level of reliability and resilience. The Alloy 400 Tube has been meticulously engineered to serve a host of uses, from mechanical and chemical equipment to piping, making it the perfect choice for a variety of projects.

Features:

Nickel Alloy C-22 is a versatile Ni-Cr-Mo-W alloy with better comprehensive corrosion resistance performance than other Ni-Cr-Mo alloys, including Alloy C-276, Alloy C-4 and Alloy 625. Alloy C-22 has outstanding resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chloride ions. It also offers optimum resistance to environments where reducing and oxidizing conditions are encountered in process streams. So it can be used where “upset” conditions are likely to occur or in multi-purpose plants.

Nickel Alloy C22 Chemical composition

| % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | P | S | V |

| min | balance | 20.0 | 12.5 | 2.0 | 2.5 | | | | | | | |

| max | 22.5 | 14.5 | 6.0 | 3.5 | 2.5 | 0.015 | 0.50 | 0.08 | 0.020 | 0.020 | 0.35 |

1. Grade : UNS N06022, N06625 ,N06600 , N06601 , N07718 , N10276 , N08800 , N08825 ,N04400 ; etc

2 . OD ( Outer Diameter ) : 6.35mm to 114.3mm

3 . WT ( Wall Thickness ) : 1.65mm to 20mm

4 . Length : As customer’s requirement

5 . Standard : ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc

6 . Technology : Cold Drawn / Cold Rolled

| Application | a) Heat exchanger |

| b) Condenser |

| c) Shipping industry |

| d) Precision machinery |

| e) Mechanical structure industry |

| f) Thermocouple & Cable etc |

Previous:Alloy C276 Nickel Alloy Smls Tube With BA/AP Tube ASTM Standard For Oil ServiceNext:Nickel Alloy C-4 ASTM B564 Seamless Nickel Alloy Tube With Annealed&Pickling Used in Acidic Environment

If you're in search of a cost-effective yet high-performing alloy solution, look no further than the Alloy 400 Tube from MT Stainless Steel. It's not just an ordinary tube; it's a testament to our relentless pursuit of quality and innovation in metallurgical technology.

Invest in our Alloy 400 Tube today and experience the remarkable difference it brings to your projects. We're not just providing a product, but a sustainable and reliable solution that adds value to your work. Embrace the MT Stainless Steel standard today with the durable and versatile Alloy 400 Tube.