MT Stainless Steel: Top Supplier of Incoloy Tube - Grade Alloy 800/800H

Grade: Alloy 800 /N08000 , Alloy 625 /N06625 , Alloy 600 /N06600 ,Alloy 601 /N06601 , Alloy 718 /N07718, Alloy C276 /N10276 , Alloy 825 /N08825 , Alloy 400 /N04400,etc

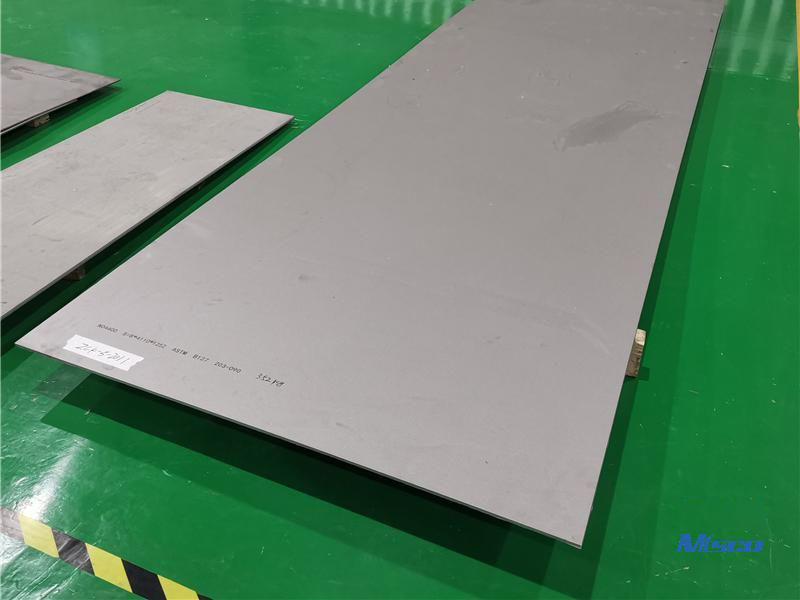

Standard: ASTM B168; ASTM B443; ASTM B670; ASTM B127;ASTM B162; ASTM B333; ASTM B575; ASTM B582; , etc

Surface: Bright Annealed

Technology: Cold Rolled

NDT: Ultrasonic test; Penetrant Test

Inspection: 100%

Packing: Pallet/Plywooden case

Quality Assurance: ISO & PED

Sheet | Plate | Strip | |

Thickness | <6mm | ≥6mm | 0.15mm-3mm |

Width | ≤1200mm | ≤2800mm | ≤1000mm |

Length | ≤3000mm | ≤8000mm | As customer’s requirement |

Application: Chemical and petrochemical process piping, heat exchangers, furnace components, carburizing equipment, heating-element sheathing, and nuclear power steam-generator tubing.

Advantages: UNS N08800 has good rupture and creep strength and excellent resistance to oxidation, carburization and sulfidation at temperatures up to 816℃. It also resists general corrosion by many aqueous media. For Applications requiring higher stress rupture and creep properties, especially at temperatures above 816℃, UNS N08810 and UNS N08811 are recommended. UNS N08800 is readily formed, welded and machined.

|  |

Through more than ten years of research and development, the production of MTSCO Alloy technology and efficiency of various materials have been greatly improved. The enterprise has passed the national quality management system certification of weapons and equipment, obtained more than 24 authorized patents, participated in the revision of 9 national standards and 3 industry standards. MTSCO has actively participated in the civil military integration project, provided high-temperature alloy materials for a PLA unit, provided high-quality special alloy materials for China ordnance industry group, and provided new low expansion alloy materials for China aviation industry. It has been successfully applied to the domestic large aircraft C919, replacing imports with domestic ones, breaking the foreign blockade monopoly and filling the domestic blank.

1 . Our company has been dedicated to producing nickel alloy tube since 2011 , owning complete producing technology and abundant managing experience .

2 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

3 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , Lloyd’s , SGS , etc , also can be provided according to customers’ requirements .

4 . The surface condition is one of our main advantages : in order to meet different requirements for surface condition , we have annealing and pickling surface , bright annealing surface , polished surface etc .

5 . In order to keep the inside surface of pipe clean and make it free from deburring , our company develops the unique and special technology — Sponge Washing with high pressure .

6 . We have complete after-sale service to deal with the problems in time.

Previous:Nickel Alloy 600 /UNS N06600 ASTM B168 Cold Rolled Sheet/ Plate with ISO/PED CertificateNext:ASTM B423 Nickel Alloy 825 Seamless Annealed& Pickled Pipe For Fertilizer

Our commitment to quality has led us to obtain ISO and PED certification, solidifying our position as a trustworthy supplier. No matter the thickness, <6mm or ≥6mm, our incoloy tubes are designed to withstand the most challenging industrial settings. Choose MT Stainless Steel for your next project and experience the unsurpassed quality of our incoloy tubes. With a rich history of successful supply and manufacturing, we stand ready to assist you in making the most suitable selection for your specific needs. Trust the experts at MT Stainless Steel to deliver the best incoloy tubes in the market. Revolutionize your industrial projects with us today.