Powerful Nickel Alloy Bar Wire - MT Stainless Steel ASTM B637 Speciality

Grade: Alloy 718 /N07718, Alloy 625 /N06625 , Alloy 600 /N06600 ,Alloy 601 /N06601 , Alloy C276 /N10276 , Alloy 800 /N08800 , Alloy 825 /N08825 , Alloy 400 /N04400,etc

Standard: ASTM B637; ASTM B166; ASTM B446; ASTM B670; ASTM B335;ASTM B637; ASTM B574; ASTM B408; ASTM B425 , etc

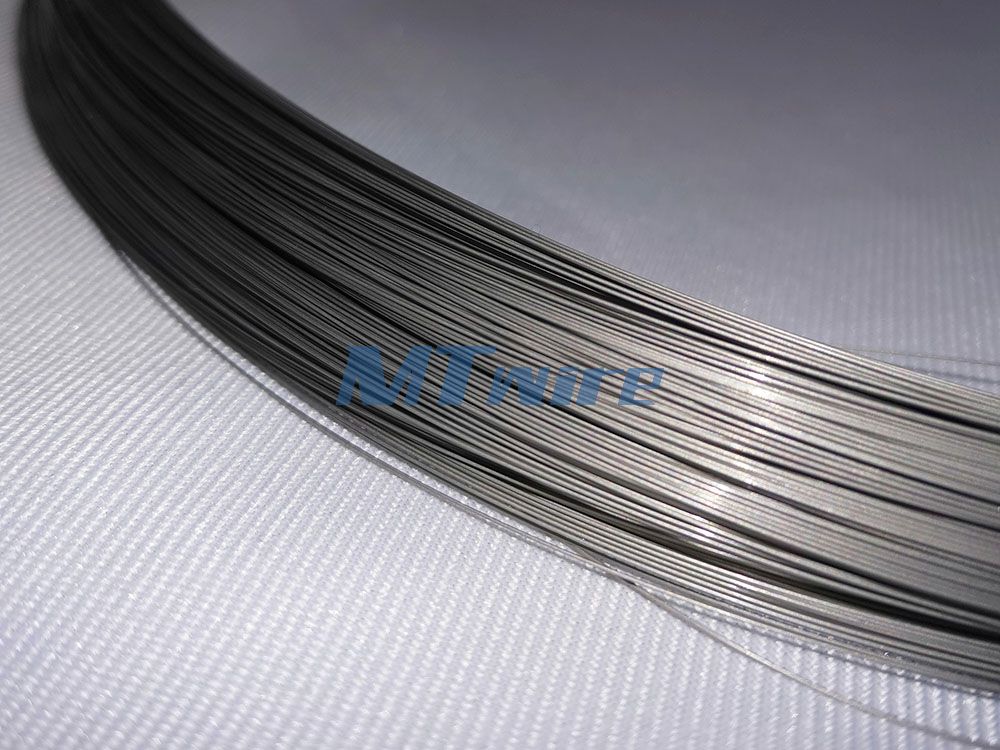

Surface: Bright Annealed/ Annealed Pickled

Technology: Cold Drawing

NDT: Ultrasonic test

Inspection: 100%

Packing: Pallet/ Plywooden case/ Wooden Reel

Quality Assurance: ISO & PED

Bar/ Rod | Wire | |

Outer Diameter | ≥10mm | 2mm-5.5mm |

Length | ≤12000mm | - |

Weight | - | ≤350KGS |

Alloy 718 / UNS N07718 Chemical composition:

% | Ni | Fe | Cr | Mo | C | Mn | Si | P | S | Co | Nb+Ta | Ti | Al | Cu | B |

min | 50.0 | balance | 17.0 | 2.80 | - | - | - | - | - | - | 4.75 | 0.65 | 0.20 | - | - |

max | 55.0 | 21.0 | 3.30 | 0.08 | 0.35 | 0.35 | 0.015 | 0.015 | 1.00 | 5.50 | 1.15 | 0.80 | 0.30 | 0.006 |

Physical properties:

| Density | 8.23 g/cm3 |

| Melting range | 1260-1335℃ |

Features: Alloy 718 is an age-hardenable nickel-chromium alloy that combines corrosion resistance with high strength and good fabricability. It has high creep-rupture strength at temperatures up to 700℃. Its excellent relaxation resistance contributes to its application in springs.

Applications: Gas turbine engines, rocket motors, nuclear reactors and spacecraft.

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

| Package | Wooden reel; woven bag or as per customer’s requirement | |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

| Quality | Test | NTD(Ultrasonic test, Eddy Current test); |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test); | ||

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature); | ||

| Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Previous:High Quality Nickel Alloy 800/800H Round/ Square Bar Raw Material With ISO CertificateNext:ASTM B574 Nickel Alloy C22/ UNS N06022 Wire With Bright Annealed Surface For Downhole Tools

Our Nickel Alloy Bar Wire is carefully packed in a Pallet/ Plywooden case/ Wooden Reel ensuring safe and secure transport. Committed to delivering excellence, our quality assurance certification from ISO & PED stands as a testament to our dedication. Our product dimensions for Bar/Rod are Outer Diameter ≥10mm and for Wire between 2mm-5mm. Dive into a world of superior strength and rigidity with our MT Stainless Steel ASTM B637 Nickel Alloy 718 (UNS N07718) Bar Wire – crafted precisely for oil field operations. Meeting international standards, we assure durability and resilience, making MT Stainless Steel your reliable partner for industrial solutions.