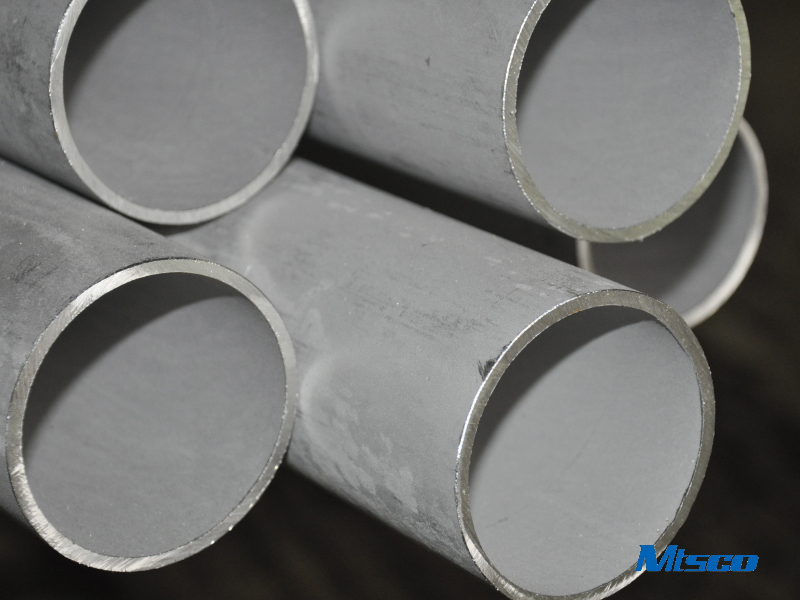

Premium Nickel Alloy 800 Seamless Pipe by MT Stainless Steel, Ideal for Acidic Environments

Experience superior quality, efficiency, and resilience with MT Stainless Steel's Nickel Alloy 800 Seamless Pipe. This product, a manifestation of advanced metallurgical science, caters to diverse requirements in both chemical and petrochemical industries, heat exchangers, furnace components, carburizing equipment, heating element sheathing, and nuclear power steam-generation tubing.

Its construction meets the exacting ASTM standards and holds an impeccable reputation for durability and resistance under highly acidic conditions. Boasting significant rupture and creep strength, this Nickel Alloy Pipe has excellent resistance against oxidation, carburization, and sulfidation up to 816℃. It stands out for its ability to resist general corrosion in a variety of aqueous media.

MT Stainless Steel goes a notch higher by recommending UNS N08810 and UNS N08811 for applications necessitating superior stress rupture and creep properties, especially at temperatures above 816℃. Our Nickel Alloy 800 Pipe is readily formable, weldable, and easily machinable, making it a versatile choice for numerous industries.

Complete with a comprehensive quality assurance program, each shipment comes with a Mill Test Certificate, while third-party inspections are always welcome. Ensuring excellent quality, we conduct a battery of tests including NTD (Ultrasonic test, Eddy Current test), Mechanical Test (Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test), Metal Test (Metallographic Analysis, Impact Test-High/low temperature), and Chemical Analysis (Photoelectric Emission Spectroscopic).

Serving the European, Middle Eastern, Southeast Asian, South American markets, and beyond, MT Stainless Steel is your trusted provider of Nickel Alloy 800 Seamless Pipes. With our commitment to quality, durability and customer-centric pricing, we aim to be your go-to supplier and manufacturer for your industrial material needs.

Previous:Nickel Alloy 718/ N07718 Annealed &Pickling For Chemical Equipment With ISO 9001Next:Nickel Alloy 825/ N08825 Big Size Seamless Pipe For Gas Downhole With ISO 9001

Application:

Chemical and petrochemical process piping, heat exchangers, furnace components, carburizing equipment, heating-element sheathing, and nuclear power steam-generator tubing.

Advantages:

UNS N08800 has good rupture and creep strength and excellent resistance to oxidation, carburization and sulfidation at temperatures up to 816℃. It also resists general corrosion by many aqueous media. For Applications requiring higher stress rupture and creep properties, especially at temperatures above 816℃, UNS N08810 and UNS N08811 are recommended. UNS N08800 is readily formed, welded and machined.

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

| Package | Iron case; woven bag or as per customer’s requirement | |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

| Quality | Test | NTD(Ultrasonic test, Eddy Current test); |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test); | ||

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature); | ||

| Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Previous:Nickel Alloy 718/ N07718 Annealed &Pickling For Chemical Equipment With ISO 9001Next:Nickel Alloy 825/ N08825 Big Size Seamless Pipe For Gas Downhole With ISO 9001