MT Stainless Steel: Phahameng ka ho Fetisisa Nickel Alloy Strip Strip Excellence- Alloy 825/N08825 e Tsamaellana le Maemo a ASTM

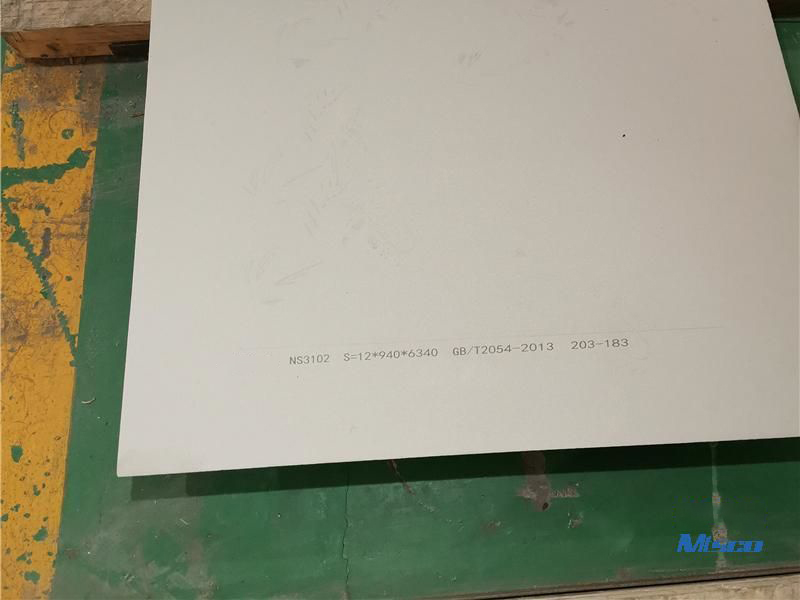

Eba le ts'ebetso e fapaneng ea Alloy 825 / N08825 Sheets and Strips, e tlisoang ho uena ke MT Stainless Steel - mofepedi ea ka sehloohong le moetsi oa lialloi tsa nickel tsa boemo bo holimo. Lipampiri tsena tsa Nickel Alloy 825 le li-strip li khomarela litekanyetso tsa ASTM B424 le B906, li netefatsa boleng ba tsona le ts'ebetso ea tsona. Alloy 825 e bonts'a khanyetso e ntle ho mefuta e mengata ea tikoloho. E ema e tiile khahlano le ho phatloha ha corrosion ea chloride-ion-induced stress. E fana ka khanyetso e matla ho fokotsa maemo a nang le phosphoric le sulfuric acid. Libakeng tse nang le oxidizing tse nang le nitric acid le nitrate, e lula e sa inehele. Ha e na tloaelo ea ho ba le likoti, ho bola ha maphao, kapa ho bola ha intergranular. Ka holim'a sena, e bonts'a thepa e tiileng ea mochine mocheso ho tloha maemong a cryogenic ho ea holimo ho ea ho 538 ℃.MT Stainless Steel e tiisa hore Alloy 825 sheet / strip e 'ngoe le e' ngoe eo e e hlahisang e finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng. Lihlahisoa tsohle li etsoa tlhahlobo e hlokolosi, ho kenyeletsoa tlhahlobo ea ultrasonic le tlhahlobo e kenang, ho netefatsa ho ts'epahala. Thomello tsohle li tla le Setifikeiti sa Tlhahlobo ea Mill, 'me Tlhahlobo ea Mokha oa Boraro e lula e amoheleha. Hore na o hloka alloy ea nickel bakeng sa ho ntša letsoai kapa lits'ebetso tse ling, MT Stainless Steel e tiisa sehlahisoa se sa finyelleng feela, empa se fetang tebello ea hau. Ka MT Stainless Steel's Alloy 825 sheets/strip, ba le phihlelo ea phapang e tlisoang ke ho khomarela litekanyetso tsa machaba le boitlamo ba boleng bo phahameng mererong ea hau. Khetha MT Stainless Steel's Nickel Alloy 825 Sheets and Strips, moo bokhabane bo lulang bo le lintlha.Ho MT Stainless Steel, re motlotlo ka ho hlahisa lisebelisoa tse ncha le tsa boleng bo holimo bakeng sa liindasteri tse fapaneng. Re hlahisa seaparo sa rona sa top-tier nickel Alloy 825/N08825, se seng se entsoe ho latela litekanyetso tsa ASTM B424/B906. Sehlahisoa sena se ikhethang ke ketsahalo e le 'ngoe ho li-ninye tse fapaneng tsa nigy 815 / N06600, Alloy 800 / N08000 400 / N04400, har'a tse ling. Sesebelisoa sa rona sa nickel alloy se ts'episa ts'ebetso e holimo khahlano le a mang a maemo a thata. E hlophisitsoe tlas'a theknoloji e batang, mochini oa rona oa alloy o tla le sebaka se khanyang, se netefatsang thepa e tsotehang ea mochine. Ho matlafatsa matla le khanyetso, Alloy 825/N08825 e loketse lits'ebetso tse sebetsang hantle. E fapana ka botenya bo fapaneng, mochini ona oa nickel alloy o amohela litlhoko tse fapaneng.

E fetileng:Nickel e Hloekileng ea 200/ UNS N02200 Nickel Alloy Sheet/ Ho qhibiliha ha Plate ka VIM le ESRE 'ngoe:Nickel Alloy 600 /UNS N06600 ASTM B168 Cold Rolling Sheet/ Plate e nang le Setifikeiti sa ISO/PED

Ntle le likarolo tsa eona tse ikhethang, li-alloys tsa rona li tla le Tiisetso ea Boleng, e ngolisitsoeng ka molao ke ISO & PED. Re tiile mabapi le taolo ea boleng; ka hona re etsa liteko tsa Ultrasonic le liteko tsa Penetrant lihlahisoa tsa rona. Tlhahlobo ea rona e 100% ka botlalo, e ts'episa feela se molemohali ho bareki ba rona. Re etsa bonnete ba hore mochini oa rona oa Nickel Alloy 825/N08825 o pakiloe ka mokhoa o sireletsehileng ka har'a li-pallets kapa mekotla ea plywooden ho netefatsa hore ho tsamaisoa ntle le tšenyo. Hore na o tsoa lekaleng la sefofane, la likoloi, kapa la lisebelisoa tsa elektroniki, mochini oa rona oa nickel alloy o tla kopana le ho feta tebello ea hau. MT Stainless Steel e ikemiseditse ho fana ka tse molemo ka ho fetisisa, ho o thusa ho fihlela katleho mererong yohle ya hao ya indasteri. Eba le phapang ea MT Stainless Steel kajeno.

Kereiti | Alloy 825 /N08825, Alloy 625 /N06625 , Alloy 600 /N06600 ,Alloy 601 /N06601 , Alloy 718 /N07718, Alloy C276 /N 04 076, Alloy C276 /N104 076 Alloy 06 08 4400, joalo-joalo |

Standard | ASTM B168; ASTM B443; ASTM B670; ASTM B127;ASTM B162; ASTM B333; ASTM B575; ASTM B582; , joalo-joalo |

Bokaholimo | Khanya Annealed |

Thekenoloji | Ho Qholotse |

NDT | Tlhahlobo ea Ultrasonic; Penetrant Test |

Tlhahlobo | 100% |

Ho paka | Sekese sa Pallet/Plywooden |

Netefaletso ea boleng | ISO & PED |

Leqephe | Letlapa | Hlobola | |

Botenya | <6 limilimithara | ≥6 limilimithara | 0.15mm-3mm |

Width | ≤1200mm | ≤2800mm | ≤1000mm |

Length | ≤3000mm | ≤8000mm | Joalo ka tlhoko ea moreki |

Nickel Alloy825 Moetso oa lik'hemik'hale:

| % | Ni | Fe | Cr | C | Mn | Si | S | Mo | Cu | Ti | Al |

| min | 38 | 22 | 19.5 | 2.5 | 1.5 | 0.6 | |||||

| max | 46 | 23.5 | 0.05 | 1 | 0.5 | 0.03 | 3.5 | 3 | 1.2 | 0.2 |

Likaroloana:Alloy 825 e na le khanyetso e ntle haholo ha e thibela ho bola ha chloride-ion-induced stress corrosion cracks, e fokotsang tikoloho e nang le phosphoric le sulfuric acid, tikoloho ea oxidizing e nang le nitric acid le nitrate, le pitting, crevice corrosion le intergranular corrosion. E na le thepa e ntle ea mochini mochesong oa cryogenic ho ea ho mocheso o itekanetseng o fihlang ho 538℃.

|  |

| Melao le Lipehelo | Theko Ntho | FOB, CFR, CIF kapa joalo ka lipuisano |

| Tefo | T/T, LC kapa joalo ka lipuisano | |

| Nako ea thomello | Matsatsi a 30 a ho sebetsa ka mor'a hore u fumane depositi ea hau (Ka tloaelo ho ea ka palo ea taelo) | |

| Sephutheloana | Nyeoe ea tšepe; mokotla o lohiloeng kapa ho latela tlhoko ea moreki | |

| Tlhokahalo ea Boleng | Setifikeiti sa Tlhahlobo ea Mill se tla fanoa ka thepa, Tlhahlobo ea Karolo ea Boraro ea amoheleha | |

| Boleng | Teko | NTD(teko ea Ultrasonic, tlhahlobo ea Eddy Current); |

| Teko ea Mechini(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test); | ||

| Metal Test(Analysis Metallographic, Impact Test-High / tlaase mocheso); | ||

| Tlhahlobo ea Lik'hemik'hale(Photoelectric Emission Spectroscopic) | ||

| Mmaraka | Mmaraka o ka Sehloohong | Europe, Middle East, Asia Boroa-bochabela, Amerika Boroa. etc |

E fetileng:Nickel e Hloekileng ea 200/ UNS N02200 Nickel Alloy Sheet/ Ho qhibiliha ha Plate ka VIM le ESRE 'ngoe:Nickel Alloy 600 /UNS N06600 ASTM B168 Cold Rolling Sheet/ Plate e nang le Setifikeiti sa ISO/PED

Ntle le likarolo tsa eona tse ikhethang, li-alloys tsa rona li tla le Tiisetso ea Boleng, e ngolisitsoeng ka molao ke ISO & PED. Re tiile mabapi le taolo ea boleng; ka hona re etsa liteko tsa Ultrasonic le liteko tsa Penetrant lihlahisoa tsa rona. Tlhahlobo ea rona e 100% ka botlalo, e ts'episa feela se molemohali ho bareki ba rona. Re etsa bonnete ba hore mochini oa rona oa Nickel Alloy 825/N08825 o pakiloe ka mokhoa o sireletsehileng ka har'a li-pallets kapa mekotla ea plywooden ho netefatsa hore ho tsamaisoa ntle le tšenyo. Hore na o tsoa lekaleng la sefofane, la likoloi, kapa la lisebelisoa tsa elektroniki, mochini oa rona oa nickel alloy o tla kopana le ho feta tebello ea hau. MT Stainless Steel e ikemiseditse ho fana ka tse molemo ka ho fetisisa, ho o thusa ho fihlela katleho mererong yohle ya hao ya indasteri. Eba le phapang ea MT Stainless Steel kajeno.