MT Stainless Steel's Nickel Alloy 400 Control Line Tubing: E etselitsoe ho sebetsa ka ho Fetisisa

Material: Alloy 400/ N04400, Alloy 825/N08825, Alloy 625/ N06625, S32205, S32750, TP316/L, TP304/L

Bophara ba Kantle: 1/4’’, 3/8’’, 1/2’’

Botenya ba Lebota: 0.035”, 0.049’’, 0.065”

Palo ea masoba: Single/Multi Core

Length : Ho ea ka litlhoko tsa bareki, ho fihlela ho 10000m

Maemo: ASTM A269/A213/A789/B704/B163, joalo-joalo.

Setifikeiti: ISO/CCS/DNV/BV/ABS, joalo-joalo.

Tlhahlobo: NDT; Teko ea Hydrostatic

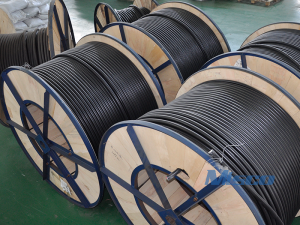

Sephutheloana: Lepolanka kapa tšepe reel

Lisebelisoa tsa polasetiki tsa ho paka | Kgutsufatso | Mocheso℃ |

Ethylene Tetrafluoroethylene | ETFE | -60 ℃ ~ 150 ℃ |

Ethylene Propylene ea Fluoronated | FEP | -110 ℃ ~ 200 ℃ |

Polyethylene e phahameng ea Density | HDPE | -60 ℃ ~ 100 ℃ |

Perfluoroalkoxy | PFA | -80 ℃ ~ 260 ℃ |

Polypropylene e fetotsoeng | PP | 30 ℃ ~ 150 ℃ |

Polyvinylidene Fluoride | PVDF | -30 ℃ ~ 150 ℃ |

Thermoplastic Vulcanisating | TPV | -30 ℃ ~ 150 ℃ |

Nylon11 | PA11 | -30 ℃ ~ 150 ℃ |

|  |

Likaroloana:Alloy 400 e na le khanyetso e ntle ea ho bola ka mekhoa e mengata e fokotsang joalo ka sulfuric le hydrochloric acid. Ka kakaretso e hanyetsana le ho bola ka mecha ea litaba ea oxidizing ho feta li-alloys tse phahameng tsa koporo. Alloy 400 e hanana le ho phatloha le ho sithabela ha kutu metsing a mangata a hloekileng le a liindasteri. E na le khanyetso e ntle metsing a leoatle a phallang, empa tlas'a maemo a sa tsitsang, ho senyeha ha likoti le liphahlo. Alloy 400 mohlomong ke eona e hanyetsanang le hydrofluoric acid ka ho fetisisa maemong ohle ho fihlela moo e belang, har'a lisebelisoa tsohle tsa boenjiniere. Alloy 400 e hlokomeleha ka ho tiea ha eona, ha e bontše tšekamelo ea ho ebrittlement mochesong oa cryogenic. Ke mosebetsi o boima.

Lisebelisoa:Lisebelisoa tsa ts'ebetso ea lik'hemik'hale, lisebelisoa tsa oli e tala, litanka tsa peterole le metsi a hloekileng, lisebelisoa tsa boenjiniere ba leoatleng, li-valve, lipompo le li-fasteners.

MTSCO esale e fana ka lithapo tsa taolo ho indasteri ea mocheso/ oli le khase ka lilemo tse fetang leshome. Lilemong tsa morao tjena, re 'nile ra tsoela pele ho etsa likhatelo-pele lefapheng la li-tubing tse pota-potiloeng, lithapo tsa ho laola likoti, le likhoele tsa ho laola ente ea lik'hemik'hale. Tsela ea rona ea ho laola e 'nile ea sebelisoa ka katleho ho mefuta e fapaneng ea mocheso, maemo a mang a thata a tlas'a metsi le a tlase, 'me ka lipatlisiso le nts'etsopele e tsoelang pele, e khona ho finyella litlhoko tse thata tsa boleng ba sebaka sa oli le liindasteri tse ling.

E fetileng:Nickel Alloy C276/ UNS N10276 Corrosion Resistance Welded Control Line Tubing bakeng sa TEC CableE 'ngoe:Nickel Alloy 625/ UNS N06625 ASTM B366 Welded Coiled Tubing for Control Line Tubing with DNV