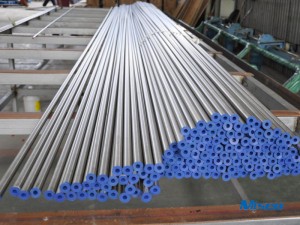

Unbeatable Nickel Alloy Heat Exchanger Tube from MT Stainless Steel

Material Grade: UNS N10276, UNS N10001, UNS N10665, UNS N10675, UNS N06022, N08800, N08825, N04400; etc

Outer Diameter: 4.5mm-355.6mm

Wall Thickness: 1.65mm-20mm

Length: Normally fixed length 6m, can as per customer’s requirement

Standard: ASTM B169; ASTM B167; ASTM B444; ASTM B622 etc

Alloy C276 Chemical composition:

% | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | P | S | V |

min | balance | 20.0 | 12.5 | 2.0 | 2.5 | - | - | - | - | - | - | - |

max | 22.5 | 14.5 | 6.0 | 3.5 | 2.5 | 0.015 | 0.50 | 0.08 | 0.020 | 0.020 | 0.35 |

| Features | Alloy C-276 has excellent resistance to localized corrosion, stress corrosion cracking, and to both oxidizing and reducing media,thus making it suitable for a wide variety of chemical process environments, including ferric and cupric chlorides, hot contaminated media (organic and inorganic),formic and acetic acids, seawater and brine solutions. It is one of the few materials that withstands the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide. |

| Applications | Chemical processing, waste treatment, pollution control, pulp and paper production, and marine engineering. |

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

| Package | Iron case; woven bag or as per customer’s requirement | |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

| Quality | Test | NTD(Ultrasonic test, Eddy Current test) |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test) | ||

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature) | ||

| Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

Nickel Alloy Tube Test:

1 . NTD(Ultrasonic test, Eddy Current test)

2 . Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test)

3 . Metal Test(Metallographic Analysis, Impact Test-High/low temperature)

4 . Chemical Analysis(Photoelectric Emission Spectroscopic)

Through more than ten years of research and development, the production of MTSCO Alloy technology and efficiency of various materials have been greatly improved. The enterprise has passed the national quality management system certification of weapons and equipment, obtained more than 24 authorized patents, participated in the revision of 9 national standards and 3 industry standards. MTSCO has actively participated in the civil military integration project, provided high-temperature alloy materials for a PLA unit, provided high-quality special alloy materials for China ordnance industry group, and provided new low expansion alloy materials for China aviation industry. It has been successfully applied to the domestic large aircraft C919, replacing imports with domestic ones, breaking the foreign blockade monopoly and filling the domestic blank.

Previous: ASTM B622 Alloy B-3 / UNS N10675 Used in Hydrochloric Acid Nickel Alloy Tube For Chemical IndustryNext:Seamless Nickel Alloy C22 Tube Custom Length ASTM B622 For Thermocouple

Experience the difference with MT Stainless Steel's Nickel Alloy Heat Exchanger Tubes and redefine efficiency and durability in the oil industry. Please note: All product specifications and materials are subject to change without notice. Confirm all details with a sales representative before purchase.