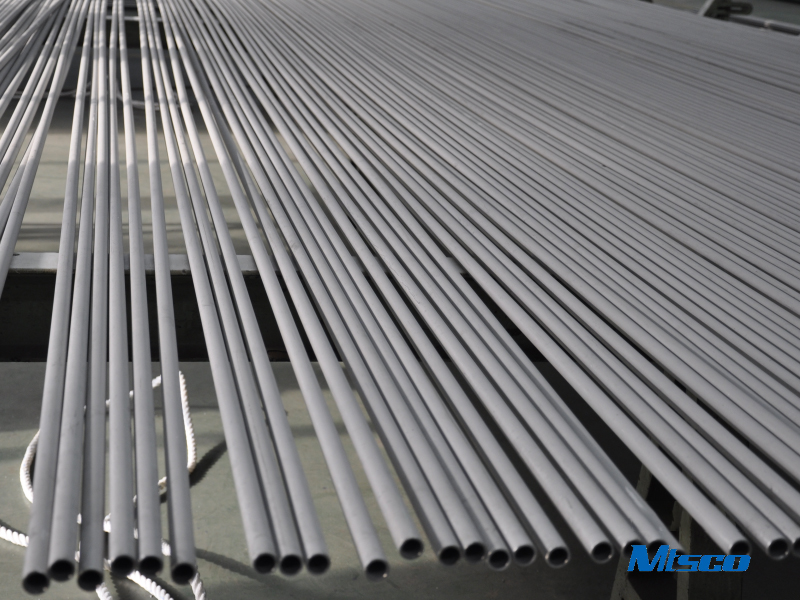

Unmatched MT Stainless Steel Alloy 601 Tube: Seamless Nickel Alloy Tubes

Material Grade: UNS N09925, UNS N08926, UNS N06625, UNS N06600, UNS N06601, UNS N10276, UNS N08800, UNS N08825, UNS N04400; etc

Outer Diameter: 6.35mm-355.6mm

Wall Thickness: 1.65mm-20.00mm

Length: Normally fixed length 6m, can as per customer’s requirement

Standard: ASTM B677; ASTM B167; ASTM B444; ASTM B622 etc.

1 . Our company has been dedicated to producing nickel alloy tube since 2011 , owning complete producing technology and abundant managing experience .

2 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

3 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , Lloyd’s , SGS , etc , also can be provided according to customers’ requirements .

4 . The surface condition is one of our main advantages : in order to meet different requirements for surface condition , we have annealing and pickling surface , bright annealing surface , polished surface etc .

5 . In order to keep the inside surface of pipe clean and make it free from deburring , our company develops the unique and special technology — Sponge Washing with high pressure .

6 . We have complete after-sale service to deal with the problems in time.

Alloy 925 Chemical composition:

% | Ni | Fe | Cr | C | Mn | Si | P | S | Mo | Cu | Ti | Al | Nb |

min | 42.0 | 22.0 | 19.5 | 2.5 | 1.5 | 1.9 | 0.10 | ||||||

max | 46.0 | 22.5 | 0.030 | 1.00 | 0.50 | 0.030 | 0.030 | 3.5 | 3.0 | 2.4 | 0.50 | 0.50 |

Alloy 925 Physical properties

| Density | 8.08 g/cm3 |

| Melting range | 1311-1366℃ |

Previous:Nickel Alloy 825/ N08825 Heat Exchanger Tube For Chemical Equipment With BA/AP SurfaceNext:Alloy B / UNS N10001 ASTM Standard Nickel Alloy Tube Seamless For Oil Industry

Endorsed by industry professionals, MT Stainless Steel's Alloy 601 Tube exhibits stellar durability and resilience against corrosive elements. Our seamless nickel alloy tubes fulfill your needs for highly reliable and hard-wearing materials that withstand harsh environments while maintaining their integrity. Not only does our Alloy 601 tube meet industrial standards, but it exceeds them. Experience the MT Stainless Steel difference with our Alloy 601 Tube, a product reflecting our commitment to excellence in materials, design, and functionality. Reinforcing industries with robust and versatile nickel alloy tubes, we continue to meet and exceed our customer's expectations one tube at a time. For seamless performance and uncompromised quality, choose MT Stainless Steel's premium Alloy 601 Tube.